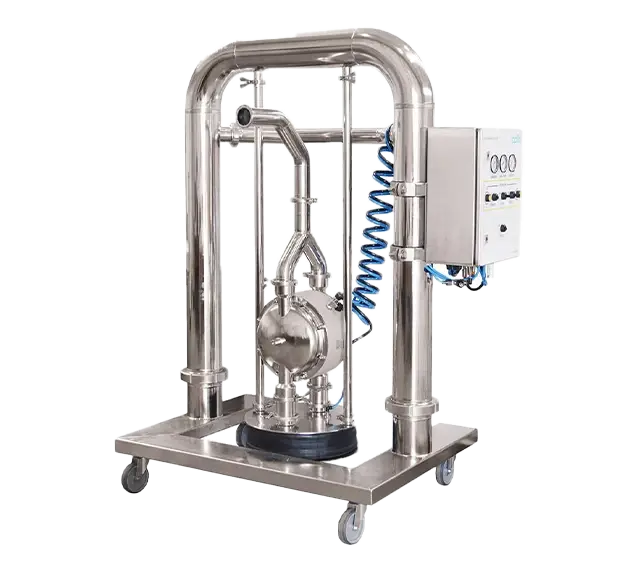

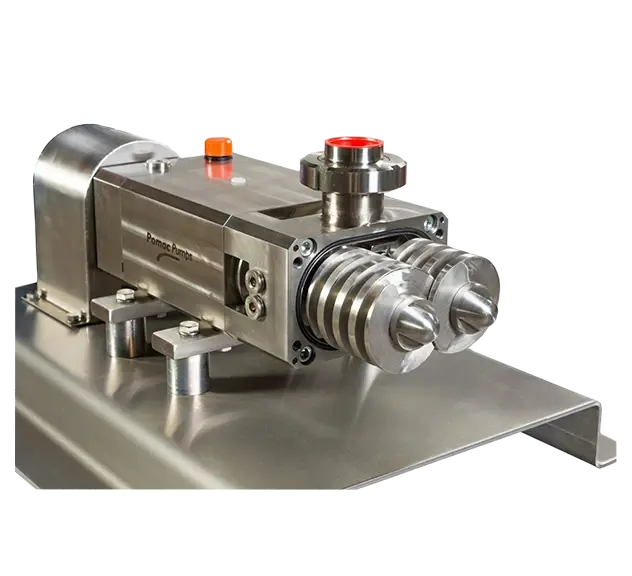

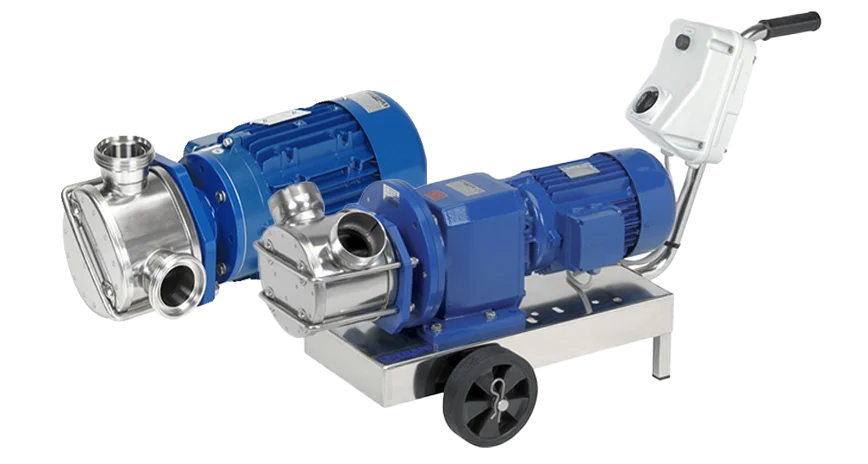

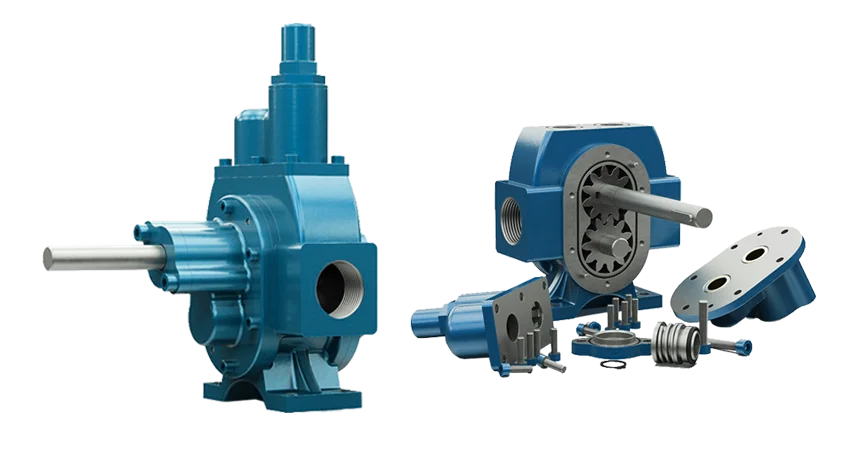

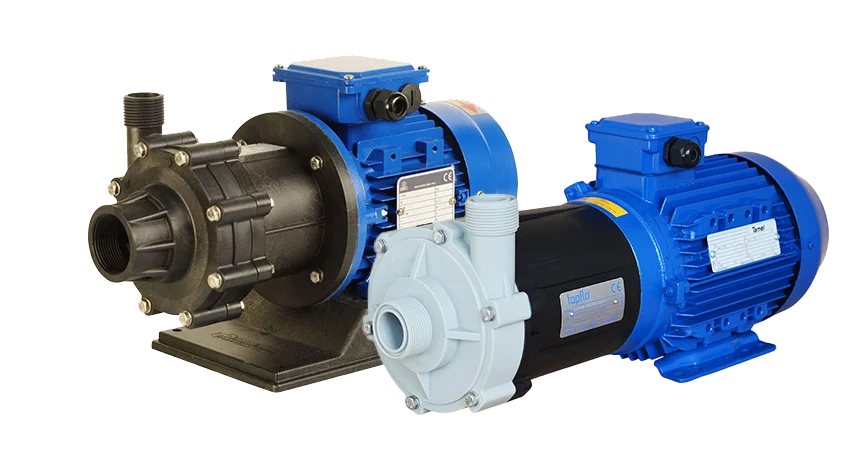

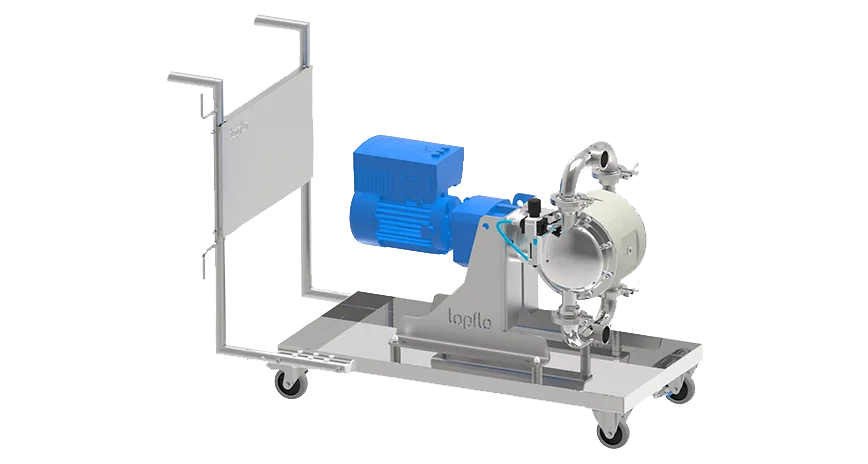

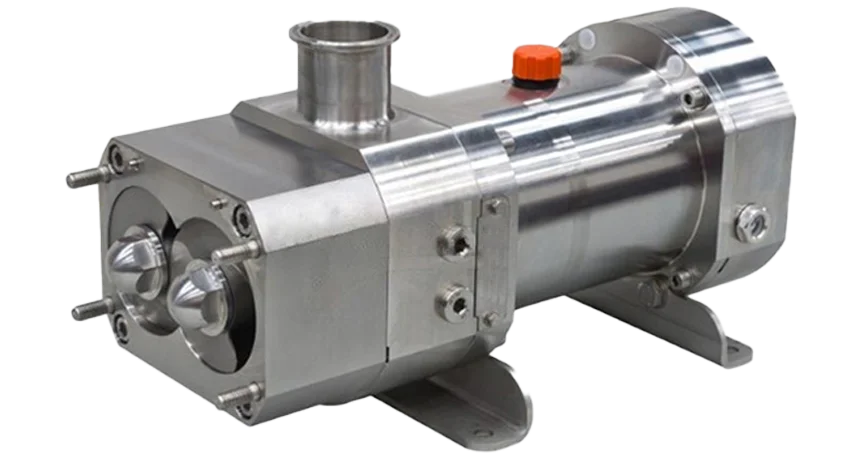

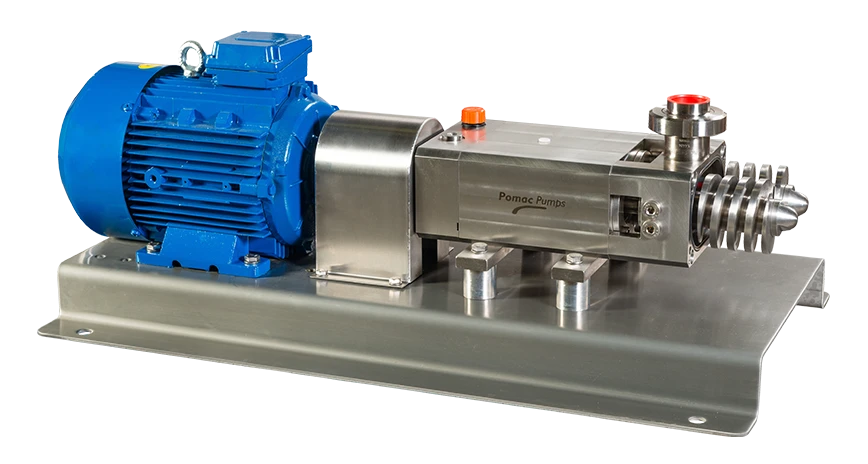

Our Magnetically Driven Internal Eccentric Gear Pump is a reliable and efficient solution based on the simple “gear within gear” principle. The rotary and idler gears in the pump head create cavities between their teeth, achieving positive displacement. Capable of pumping liquids that are too viscous for a standard Centrifugal Pump, these pumps, featuring only 2 moving components within the process medium, delivers efficient suction lift and bi-directional operation, ensuring optimal efficiency and versatility. Additionally, this ATEX-available Gear Pump delivers smooth and accurate performance, making it an excellent choice for various applications.

Typical applications for our Magnetically Driven Internal Eccentric Gear Pump:

Overview

Features & Benefits

Specifications

Gear Pumps are classified as Rotary Positive Displacement Pumps and are well-suited for the transfer of viscous and semi-viscous fluids for a range of applications and industries.

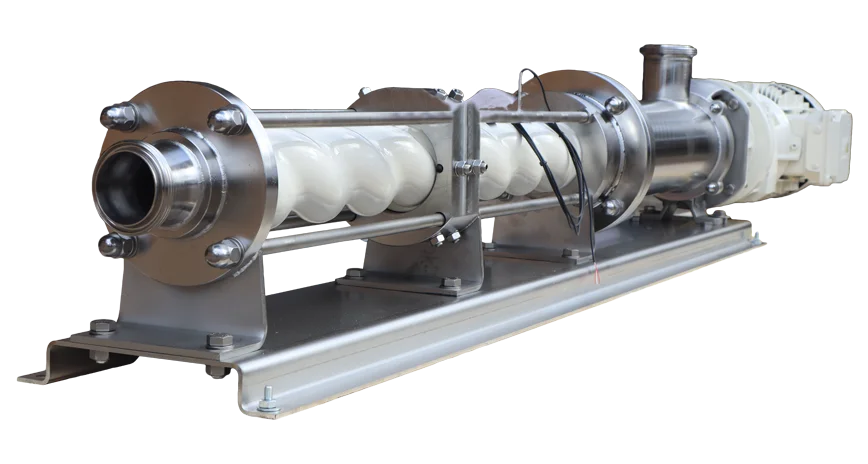

How does an Internal Eccentric Gear Pump work?

Fluid entering the pump: The orange coloured section in the image represents the process medium as it is entering the pump suction port, pump casing & filling the cavities between the Idler Gear (Red) & Rotary Gear (Brown). The 3 arrows indicate the direction of fluid passage through the pump and rotational direction of the gears.

Fluid filling the cavities & split of flow: As the fluid progresses through the pump head and fills the cavities between the gears it is also separated by the crescent shape in the pump head, which acts as a seal preventing back flow between the suction & discharge ports.

Pump almost flooded: As the fluid fully fills the casing all cavities between the gears are completely filled in the form of locked pockets of fluid to guarantee absolute volume control and enable the pump to deliver a fixed volume per revolution.

Pump is flooded & starts to discharge the process medium under pressure: Once the pump is fully flooded, the rotor and idler gears mesh together and form a liquid seal which is equidistant between the pump ports which then enables the fluid to exit the discharge of the pump under pressure. The delivery pressure is dependent on the installed power of the motor.

- Accurate and pulseless flow at high differential pressures

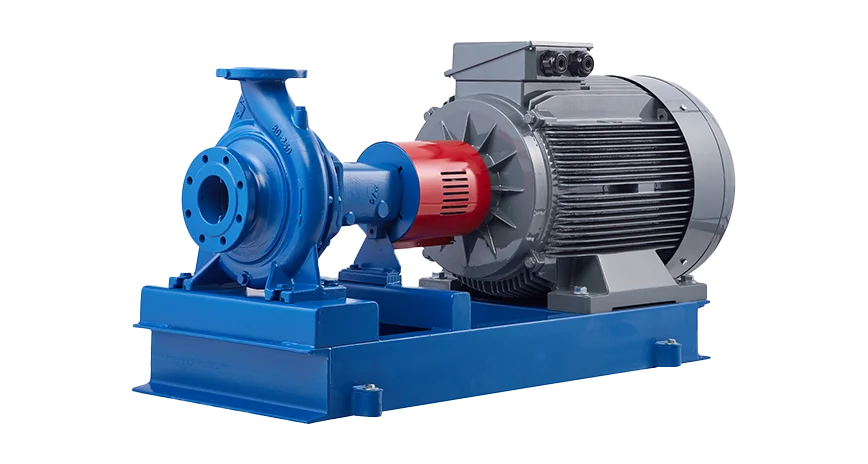

- Ability to pump fluids too viscous for Centrifugal Pumps (higher differential pressures than Centrifugal Pumps)

- High mechanical efficiency across different pressures and varying flow

- Efficient suction lift applications

- Ability to operate at different points on their curves as flow is proportional to rotational speed

and pressure is dependent on the installed motor power

- Bi- Directional flow

- ATEX-available for use in hazardous environments

| Max Capacity (m³/hr) |

55m³/hr |

| Max Pressure (m) |

120m |

| Viscosity (cSt) |

up to 5,500 cSt |

| Max Speed (rpm) |

1400 rpm |

| Max Temperature (°C) |

250°C |

| Materials & Limits |

| Connection Sizes |

1½” – 2½” |

| Capacity Range |

0.1 – 55 m³/hr |

| Pressure Range |

10 – 120m |

| Temperature Range |

up to 250ºC |

| Speed Range |

20 – 1500 rpm |

| Viscosity Range |

10 – 5,500 cSt |

| Pump Body & Cover |

Cast Iron, Spheroidal Cast Iron, Cast Steel, Stainless Steel AISI 304/316 |

| Gears |

Spheroidal Cast Iron, Cast Steel, Stainless Steel AISI 304/316, CrNi Stainless Steel |

| Bearings |

SnBz12 Bronze, Carbon Graphite, Silicon Carbide, Hard Metal Coated Steel |

| Sealing |

Sealless Mag-Drive |

Sizes Available:

| Model |

Max Flow (m³/hr) |

Max Pressure (Bar) |

Viscosity Range (cSt) |

Max Speed (rpm) |

Max Temperature (°C) |

| YMG 1½ |

5.7 |

12 |

10 – 5,500 |

1400 |

250 |

| YMGF 2 |

15 |

12 |

10 – 5,500 |

500 |

250 |

| YMGF 2½ |

25.5 |

12 |

10 – 5,500 |

500 |

250 |

| YMGUF 2½ |

32 |

12 |

10 – 5,500 |

500 |

250 |

| YMGF 3 |

32 |

12 |

10 – 5,500 |

500 |

250 |

| YMGBF 3 |

55 |

12 |

10 – 5,500 |

500 |

150 |