| Pump Size | Motor Power kW | Pump Speed RPM |

|---|---|---|

| PT 38 | 1.5 | 2.2 | 20, 25, 31 | 34, 44, 50, 61 |

| PT 40 | 2.2 | 3 | 4 | 25, 31, 33, 41 | 47 | 54, 63 |

| Pump Size | Motor Power kW | Pump Speed RPM |

|---|---|---|

| PT 38 | 1.5 | 2.2 | 20, 25, 31 | 34, 44, 50, 61 |

| PT 40 | 2.2 | 3 | 4 | 25, 31, 33, 41 | 47 | 54, 63 |

Download Brochure

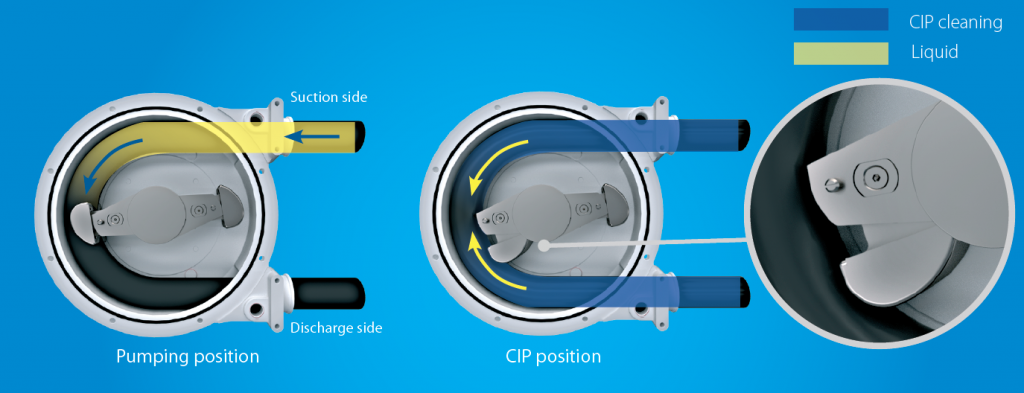

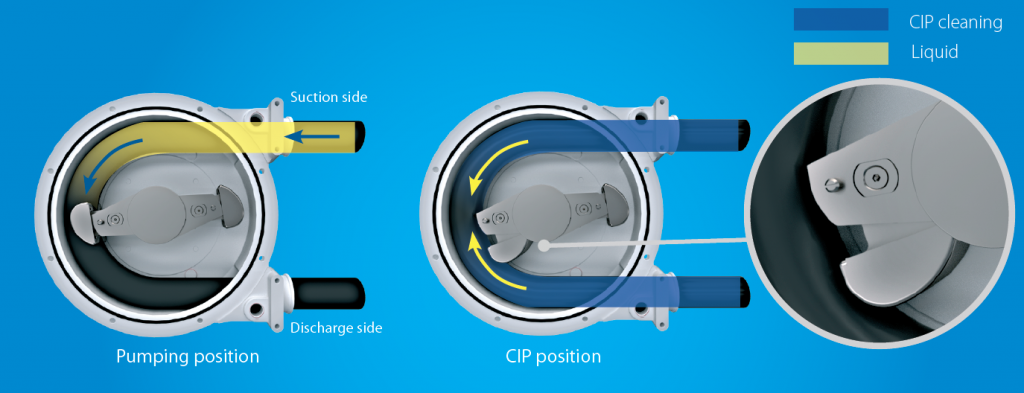

The smart design of our CleanPRO CIP Peristaltic Pump eliminates hose compression during the cleaning process by reversing the pumps direction and automatically retracting the shoes. This optimises the lifespan of the hose and pump, reducing production downtime and keeping maintenance costs low:

Application coverage:

Covering a range of hygienic applications, this pump excels in the following applications:

The smart design of our CleanPRO CIP Peristaltic Pump eliminates hose compression during the cleaning process by reversing the pumps direction and automatically retracting the shoes. This optimises the lifespan of the hose and pump, reducing production downtime and keeping maintenance costs low:

Application coverage:

Covering a range of hygienic applications, this pump excels in the following applications:

| Technical Data | Specification |

| Casing Material | Nodular cast iron |

| Hose Material (wetted) | NR FDA (std), NBR FDA, EPDM FDA |

| Insert Material (wetted) | AISI 316L |

| Connection Type | DIN 11851 thread, SMS 3017 clamp, DIN 32676 clamp |

| Motor* | IEC standard, 3-phase, 4-pole, 50/60 Hz, IP55+PTC |

| Max Capacity | 12m³/h |

| Max Liquid Temperature | 80 ºC** |

| Max Discharge Pressure | 10 Bar |

| Max Suction Lift | -0.9 Bar |

*Other motor options available on request

**At a room temperature of 20°C. Furthermore, it depends on the pumped fluid and on the hose material

Available Hose Materials:

| Hose | ATEX | Industry | ||||||||

| Water Treatment | Ceramic | Mining & Quarries | Building & Construction | Chemical | Food & Beverage | Pharma & Cosmetics | Print, Pulp & Paper | Agriculture & Biogas | ||

| Industrial | ||||||||||

| NR | X | X | X | X | X | X | X | X | ||

| NBR | X | X | X | X | ||||||

| EPDM | X | X | X | X | X | X | X | X | X | |

| CSM | X | X | X | X | ||||||

| Food Grade | ||||||||||

| NR FDA | X | X | X | |||||||

| NBR FDA | X | X | ||||||||

| EPDM FDA | X | X | ||||||||