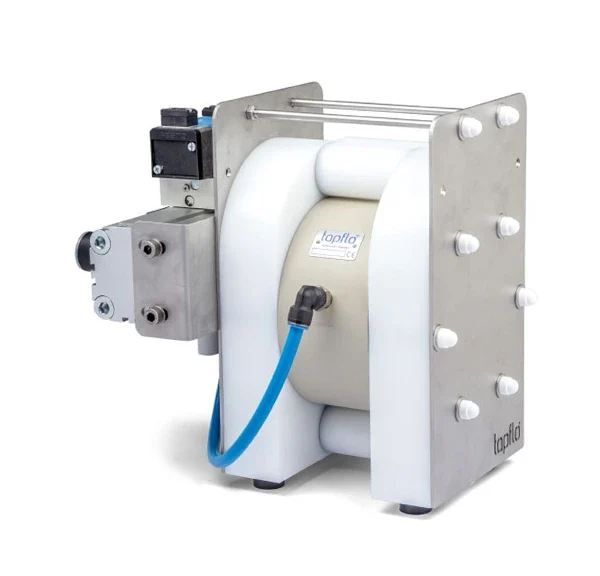

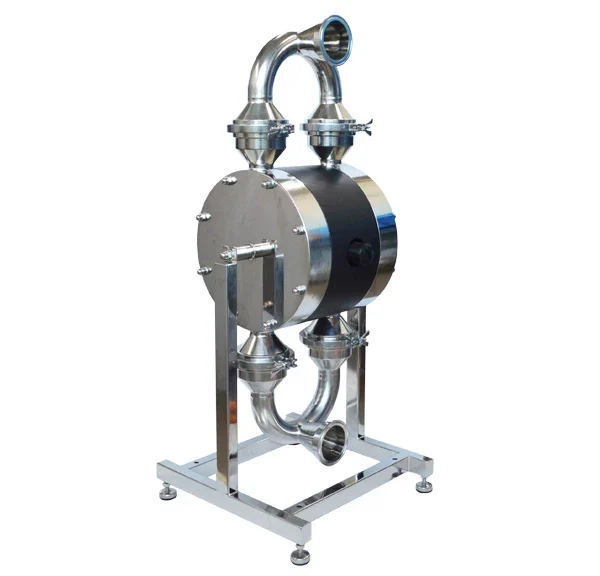

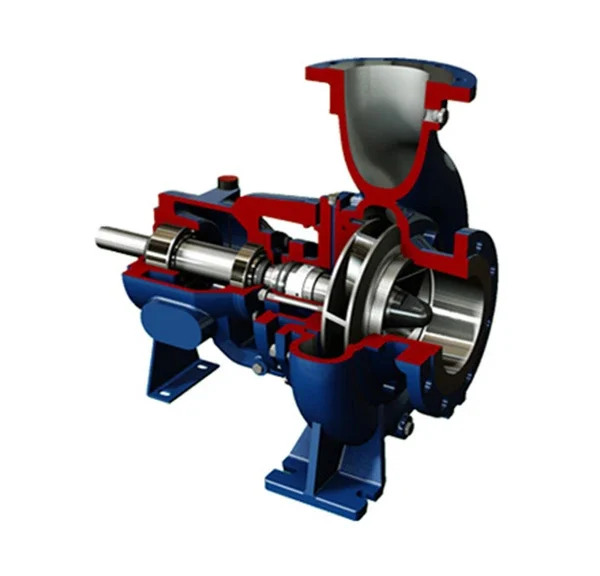

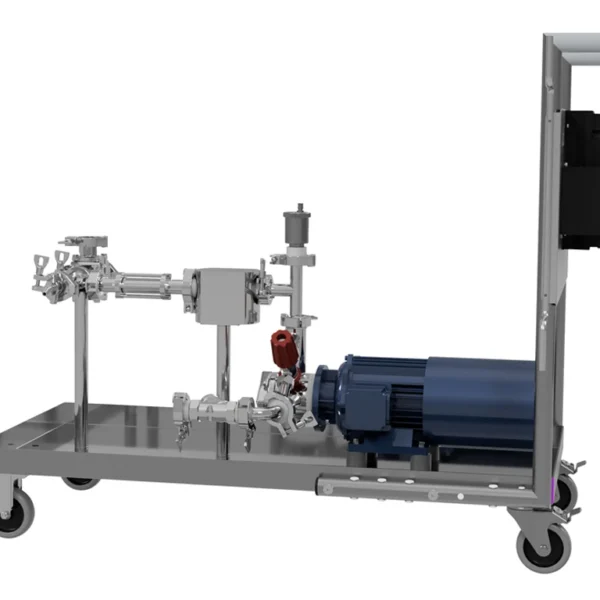

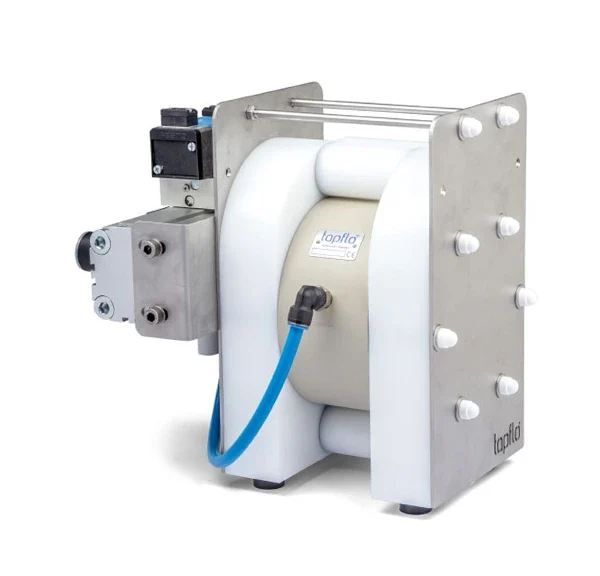

Our Pumps and Systems adhere to stringent industry and sanitation standards, holding certifications such as EHEDG Certification, FDA Declaration of Conformity, ATEX Directives and more, ensuring complete peace of mind when making use of a Tapflo Pump.