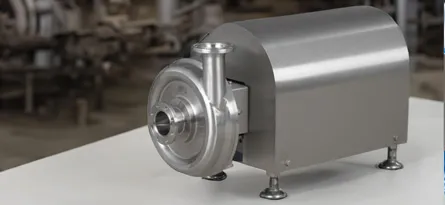

CPC Pump

The CPC Sanitary Centrifugal Pump is manufactured by Pomac Pumps and has been designed to EHEDG guidelines making it ideal for hygienic applications. If you’ve been having problems with your CPC Pump, try our troubleshooting guide below or if it continues, contact the team at Tapflo UK for help.

Malfunctions

What are the main causes of malfunction of the CPC Sanitary Centrifugal Pump?