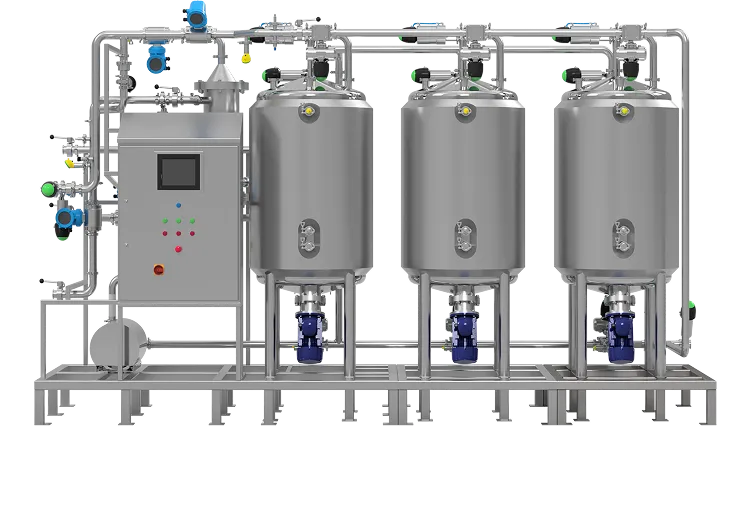

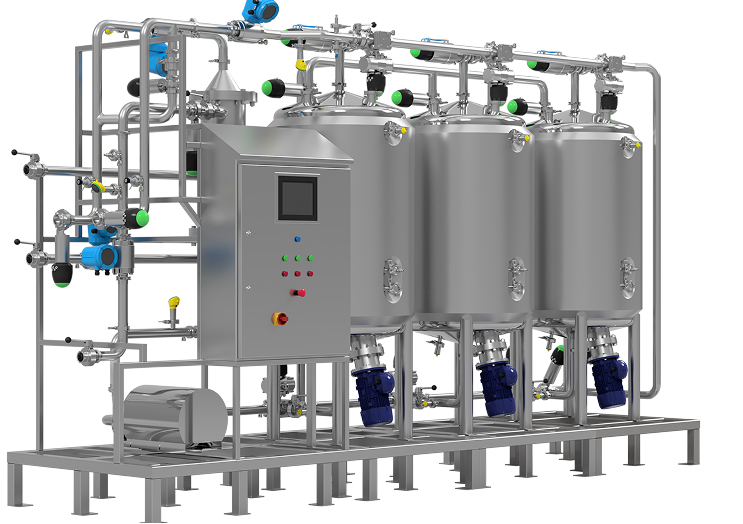

Bleach Blending System (Chemicals)

AUTOMATED DOSING, MIXING, & DILUTION FOR PRECISION PRODUCTION

Achieving the perfect blend of ingredients while maintaining strict proportions, accuracy, and efficiency is a challenge for industrial manufacturers. Our Bleach Blending System removes the complexity by fully automating the process, delivering precise, recipe-driven production with no manual intervention.

Designed with a modular approach, this system adapts to your specific needs, handling everything from high-viscosity liquids to delicate formulations. By optimising production time, reducing ingredient waste, and ensuring complete traceability, it enables cost-efficient, scalable manufacturing without compromising product quality.

- Eliminates waste with automated dosing for exact ingredient proportions

- Achieves homogenous, stable mixtures instantly, streamlining production

- Enables flexible scheduling with uninterrupted product output

- Tracks operational parameters with comprehensive data logging

- Manage production on-site or via remote access for ultimate flexibility