What does ”Dry running a Pump” mean?

Dry Running is an undesirable condition that affects most pump designs and is characterised when a pump operates without an adequate amount of fluid. In most pump technologies, this leads to cavitation and critical damage to the internal pumping elements such as impellers, lobes, gears, casings, seals and bearings.

Why does dry running a pump happen?

Dry running is usually related to how the pump is operated, monitored and controlled and is typically a result of human error. Companies generally rely on their operators to monitor the pumps on the line, however, problems will arise when a pump is unintentionally left running for prolonged periods of time after the intended operation has been completed. For example, during offloading of a tanker, an operator may leave the pump unattended whilst the tanker is being evacuated and the pump may over-run when the tanker is empty, thus resulting in damage to the pump internals.

Why shouldn’t I dry run my pump?

If you are instructed by the manufacturer that a pump can’t dry run, there are several reasons for it and it’s important to avoid it.

- Dry running could lead to mechanical seals wearing quickly which could cause the pump to leak. This will allow the potentially hazardous liquid to spill, putting pump operators at risk.

- Dry running can damage your pump which could cause an immediate stop to your production line. This could cause a loss of production, resulting in unnecessary delays and high costs to your business

- Parts will wear quickly from the damage caused, resulting in expensive spares bills

- Risked cavitation if dry running for long periods of time. The whole pump to need to be replaced if there has been serious damage to the impellers in your pump.

Dry Running can be extremely costly to your business so please check with your supplier or the pump manufacturer whether the pump you’ve purchased can be dry run before operating it.

How to avoid dry running

When using most pump designs, such as Rotodynamic as well as Reciprocating and Rotary Positive Displacement Pumps, most companies need to install protection and control devices on the pumps and system to ensure that the pump is stopped immediately after the pumping operation is complete, or in the absence of fluid at the pump suction or source.

Generally, there are 3 different methods used for protecting pumps from Dry Running:

- Pressure or Level Switch Protection: Pressure Switches fitted to the suction pipe or port of the pump(s) or Float Switches/Electrode Relays in the Supply tank

- Pressure Transmitter Protection: Measurement of the inlet pressure of the pump(s) by means of an analogue pressure transmitter

- Level Transmitter Protection: Measurement of the supply tank fluid levels by means of an analogue level transmitter such as an Ultra-Sonic Level Sensor.

On-site engineers and operators spend significant amounts of time ensuring pumps are properly installed and primed, significantly increasing the cost and complexity of the installation. However, despite all these efforts, the ever-present possibility of human error, malfunctioning control and monitoring equipment, unpredictable events and improper use of equipment means that Dry Running is never completely eradicated. As a result, plant owners are constantly in search of technology and solutions that can prevent or avoid the costly and damaging effects of Dry Running in order to reduce maintenance costs, increase throughput and alleviate pressures put onto operators to constantly monitor, control and protect their equipment on the line.

Preventing problems associated with dry running

There are a variety of standard accessories that can be used to control pumping equipment to protect it from dry running such as pressure and temperature sensors. Additional accessories and expensive sealing systems aren’t always the answer. Not all pumps are created equally, and at Tapflo UK, we have a variety of pump solutions that will allow you to dry run your pump without causing damage to it. Need your pump to run dry? Let us know when you call us.

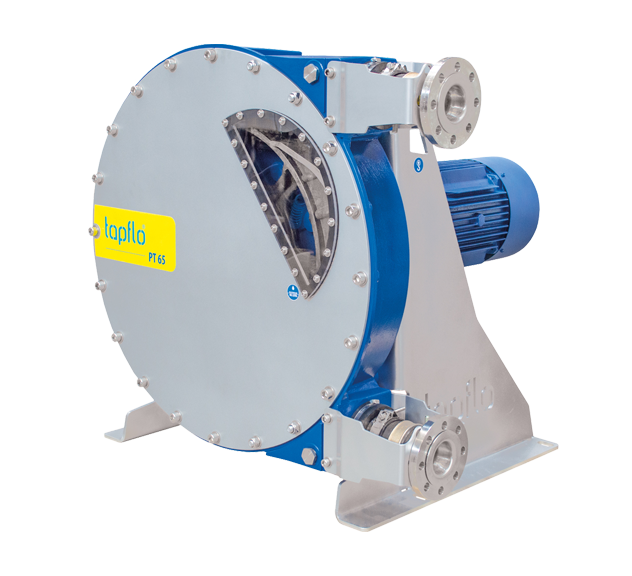

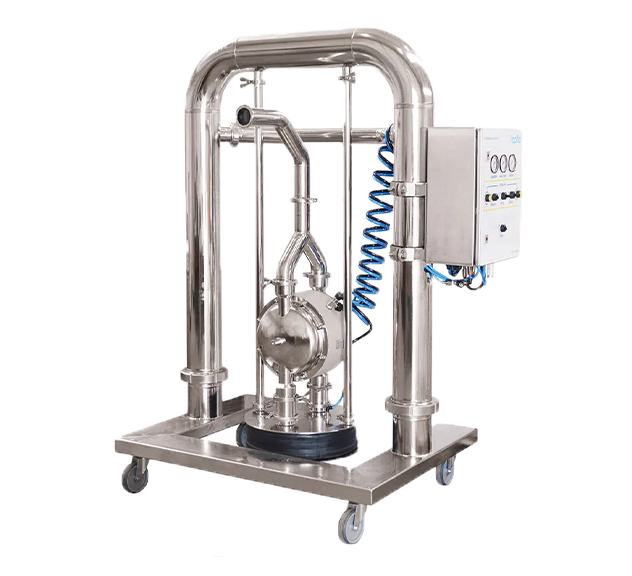

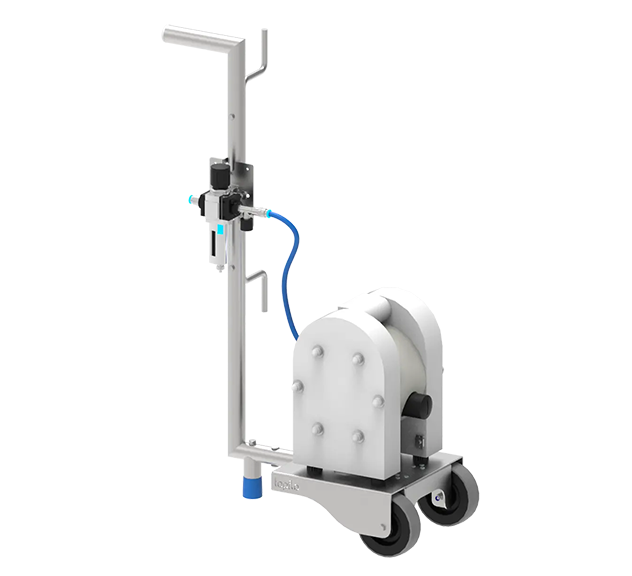

Tapflo offer a range of pump technologies that have the added benefit of being able to dry run, including our Diaphragm Pumps and Peristaltic Pumps which can run dry indefinitely without damaging the pump.

Due to their design and construction, both of these pumping technologies are able to operate under dry conditions without experiencing common wear problems associated with dry running. Not only does this alleviate the pressure put on the operator, but it also simplifies the pumping system and reduces the cost of installation and ownership significantly. Of course, these designs, on their own, do not overcome the energy costs affiliated with overrunning equipment. To improve this, Tapflo offers dry run protection devices such as our Pneumatic Guardian System for Diaphragm Pumps. This Guardian System automatically stops your pump when the pumping process is complete.

Looking for pumps that offer dry running capabilities? Our dry-run pump range includes:

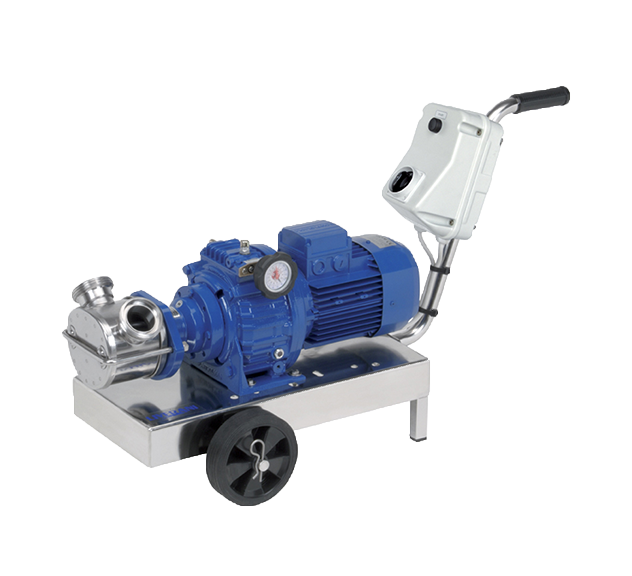

Close Coupled Liquid Ring Self-Priming Pump

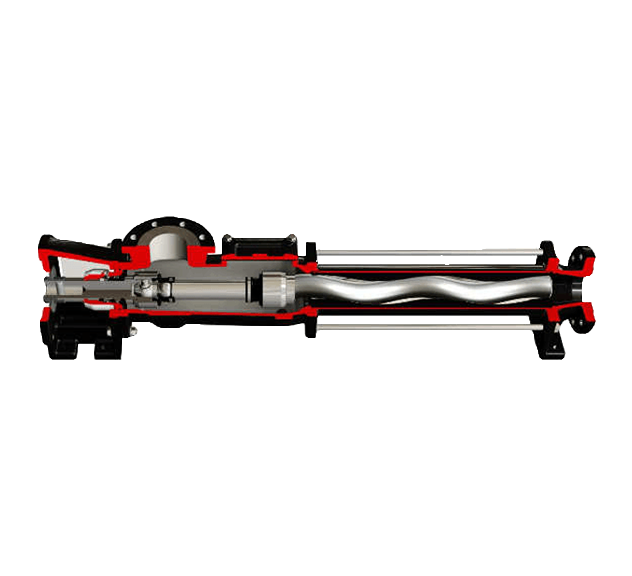

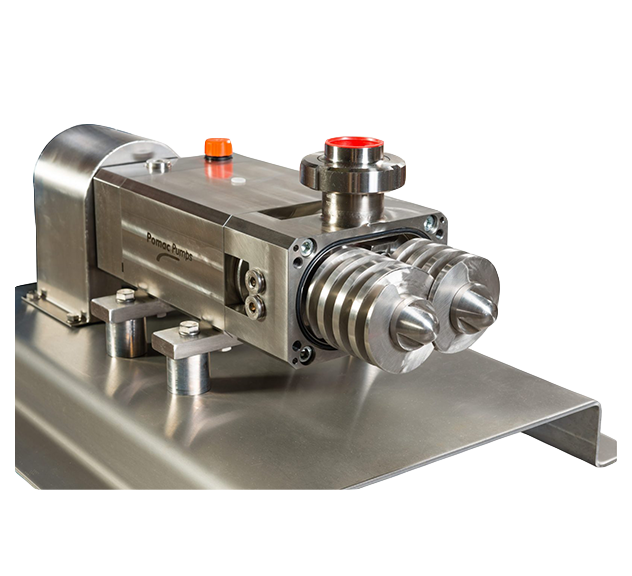

Our range of Mag Drive Regenerative Turbine Pumps can be delivered with optional dry running protection.

In summary, Tapflo UK have a full range of pumping solutions which can either protect equipment from Dry Running or indeed avoid problems associated with Dry Running completely! Let’s discuss your options today.