Stainless Steel Tanks are the backbone of numerous industries, offering unmatched durability, hygiene, and adaptability. From compact 50L vessels to colossal 180,000L storage solutions, these tanks cater to an array of applications, from brewing and food production to chemical processing and water storage.

Capacity

250 Litre

Material

Stainless Steel (304 or 316)

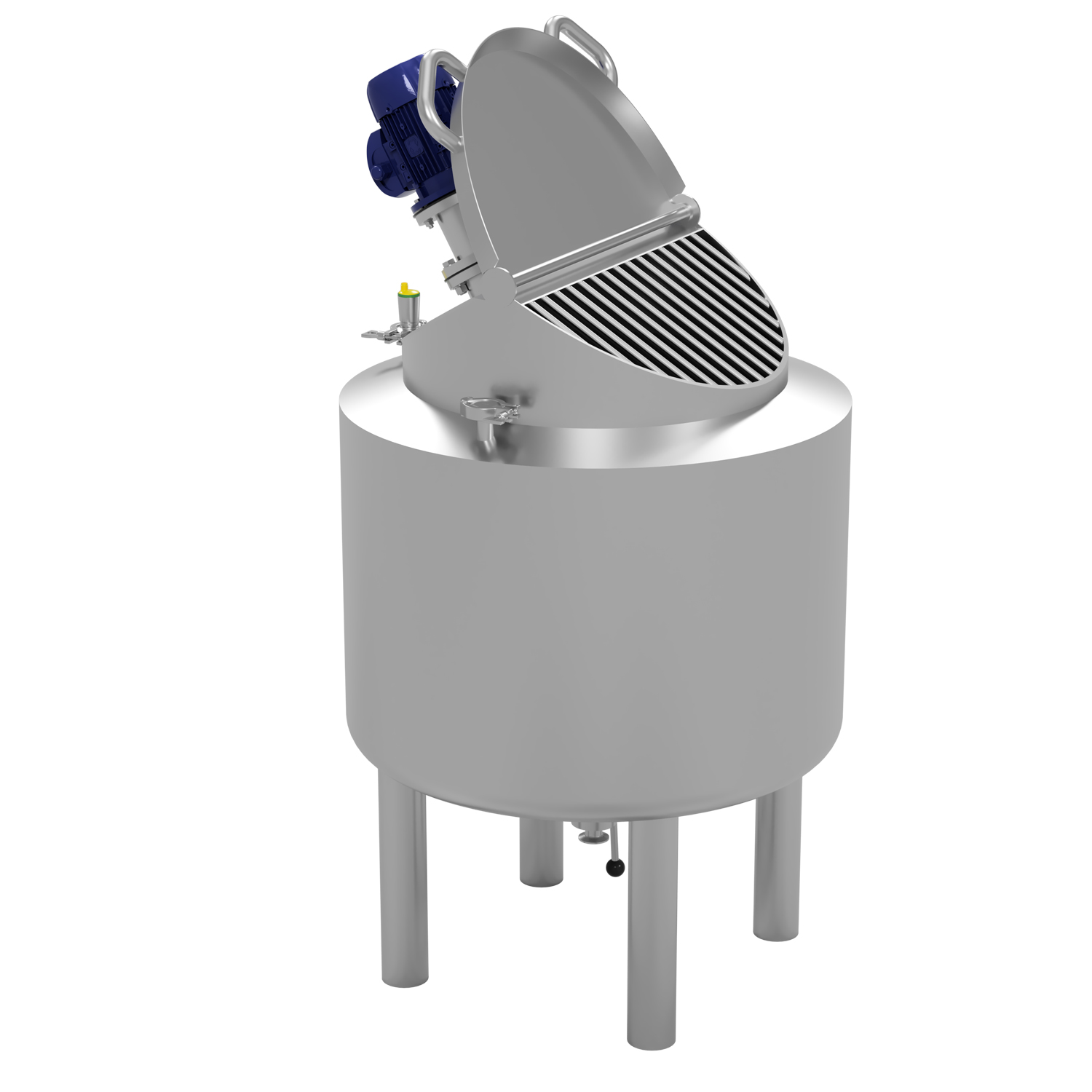

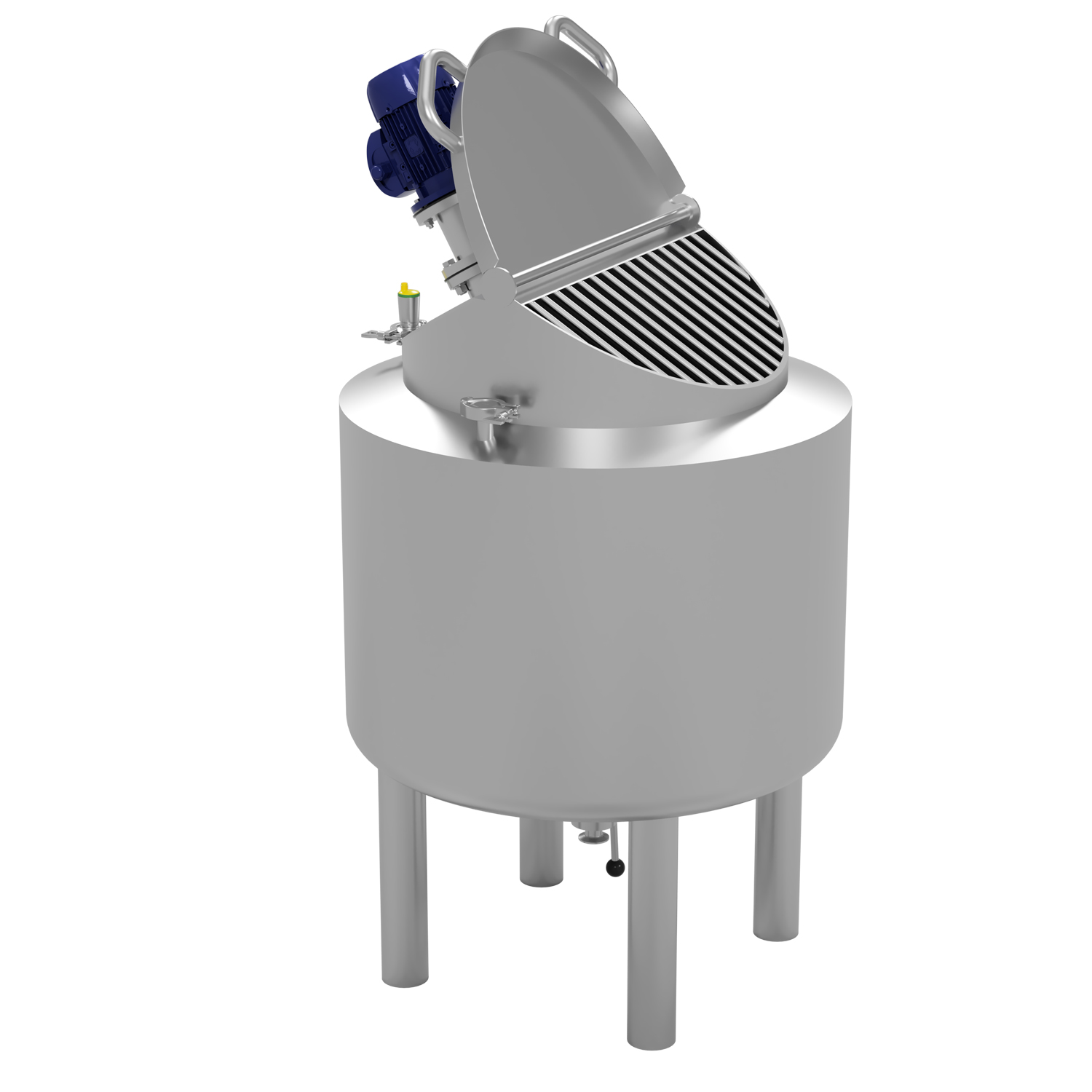

250ltr Stainless Steel Process Tank

Capacity

1000 Litre

Material

Stainless Steel (304 or 316)

1000ltr Stainless Steel Conical tank

Capacity

20,000 Litre

Material

Stainless Steel (304 or 316)

20,000ltr Stainless Steel Tank

At Tapflo UK, we take pride in offering bespoke solutions that go far beyond standard tanks. Whether it’s industrial trolleys, integrated pipework, or tailored skids, our expertise ensures that every product is designed to fit seamlessly into your specific processes. From one-off prototypes to full-scale production runs, we’re here to enhance your operations and optimise efficiency, no matter the scale!

Our Stainless Steel Tanks are available in a wide range of shapes, sizes and configurations to meet diverse operational requirements. Some examples of Tanks we’ve supplied recently include:

Contact us to discuss tailored solutions for your stainless steel tank requirements.

Experience the benefits of stainless steel. Get in touch to find the right tank for you.

Stainless Steel mixing tanks are designed for blending liquids, powders, and other materials. These tanks are equipped with agitators, mixers, or paddles to ensure consistent mixing, handling everything from viscous solutions to delicate emulsions. They are ideal for food preparation, chemical formulations, and pharmaceutical applications.

For industries requiring the storage of bulk powders or granules, Stainless Steel powder storage tanks provide a secure, contamination-free solution. Their smooth surfaces prevent material buildup, ensuring easy cleaning and efficient product flow.

Durable and corrosion-resistant, chemical transfer tanks are essential for safely transporting or storing aggressive substances. These tanks can be fitted with special linings or coatings for added protection and feature custom nozzles or fittings to suit specific processes.

Hygiene and safety are critical in food and beverage production. Stainless Steel tanks are used to store, ferment, or process products like sauces, dairy, beer, and wine. Their easy-to-clean surfaces and resistance to bacteria make them the preferred choice for food-grade applications.

For applications requiring temperature control, heated and insulated Stainless Steel tanks are an excellent choice. These tanks are designed with cavity walls, polyurethane foam insulation, or conditioning belts to maintain precise temperatures for sensitive materials such as chocolate, oils, or chemicals.

Stainless Steel water storage tanks ensure durability and hygiene, whether for potable or non-potable water. These tanks resist corrosion and maintain water quality, making them ideal for residential, commercial, and industrial uses, including rainwater harvesting and process water storage.

Designed for durability, these tanks handle the storage and treatment of wastewater, slurries, or recycled materials. Stainless Steel’s robustness ensures a long lifespan even in demanding environments, such as recycling facilities or industrial wastewater systems.

Precision and sterility are critical in the pharmaceutical and biotech sectors. Stainless steel tanks are widely used for mixing, fermenting, or storing sensitive materials in these applications. Features like electro-polished surfaces and customizable fittings ensure compliance with stringent standards.

Discover the perfect tank for your industry. Reach out to explore our versatile options.

Call us:

02380 252 325Email us:

[email protected]Contact our experts today for further information

If you are having trouble finding the suitable pump for your needs please contact

02380 252 325