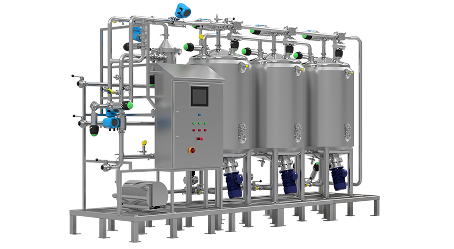

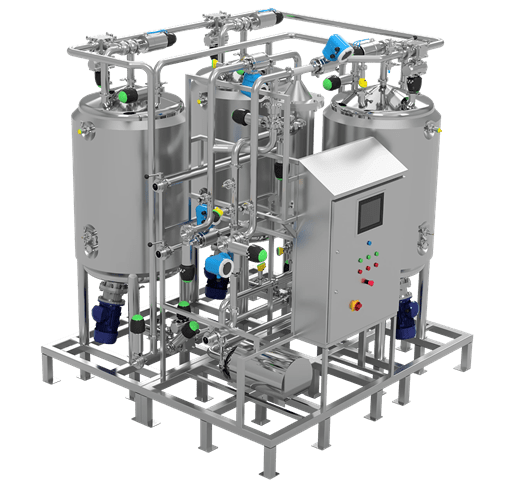

Our Modular CIP System is a pre-assembled, scalable cleaning system tailored for industries with diverse and evolving cleaning requirements. Designed for seamless integration into existing facilities, this system minimises installation time and operational disruption, delivering consistent, high-quality cleaning performance while reducing utility consumption and maximising operational uptime.

Built off-site for fast use, the Modular CIP System arrives ready for integration. With tanks, Centrifugal Pumps, heat exchangers, flow meters, and automated controls, this system delivers reliable and repeatable cleaning cycles. All critical parameters, such as flow, temperature, concentration, and timing, are adjustable to meet regulatory and production requirements. The system operates at temperatures up to 90°C and is built entirely with FDA-compliant Stainless Steel.

Every Modular CIP System is custom-built to your process needs. There are no restrictions on tank sizes, pipe diameters, or layout, ensuring the system is designed around your facility

Whether you require compact setups or large-scale multi-tank systems, this solution scales to your cleaning demands. It supports multi-stream CIP processes with multiple pump configurations, making it ideal for larger, more complex operations

Built with 304/316 Food-Grade Stainless Steel and washdown-rated components, the system is designed for long-term reliability and sanitary operation

Integrated data logging ensures traceability and quality assurance, helping meet FDA, cGMP, and other regulatory standards

PLC-controlled with programmable cleaning cycles, reducing manual intervention and improving process repeatability

Pre-assembled modular design means reduced on-site fabrication, faster deployment, and minimal disruption to ongoing production

The system can be accessed via a secure, end-to-end encrypted network connection, allowing diagnostics and software upgrades to be carried out remotely

From single-tank startup systems to fully scaled multi-stream cleaning lines, this is a CIP solution designed to evolve with your production

Optimised water, chemical, and energy usage results in lower operating costs without compromising on cleaning performance

Pre-Rinse | with recovered water

Temp | Ambient °C

Duration | 5-10 min

Alkali Clean | 2% Caustic Solution

Temp | 70–80°C

Duration | 10 – 20 min

Inter-Rinse | with process water

Temp | Ambient °C

Duration | 5 – 20 min

Acid Clean | 1% Phosphoric Acid

Temp | 50–70°C

Duration | 2 – 10 min

Inter-Rinse | with process water

Temp | Ambient °C

Duration | 5 – 20 min

Final Rinse | Quality (Purified) Water

Temp | Ambient °C

Duration | 5 – 20 min

Air Purge | Sterile Air

Temp | 20–30°C

Duration | 3 – 15 min

Tank Sizes:

1,000L up to 10,000L+, depending on application

Flow Rates:

Flows from 5m³/hr up to 25m³/hr+

Pressures:

1 – 6 Bar+

Components:

Tanks, Centrifugal Pumps, heat exchangers, flow meters, conductivity sensors & temperature sensors

Cycle Types:

Supports alkali, acid, rinse & air purge cycles with customisable time, flow & concentration settings

Capacity:

Scalable for small to large facilities, with tank sizes & pump capacities tailored to customer requirements

Automation:

Features a user-friendly PLC interface for programming & monitoring cleaning cycles

Temperature Range:

Operates effectively up to 90°C for caustic cleaning

Material:

Constructed using FDA-compliant Stainless Steel (304/316), ensuring durability & sanitation

Our Modular CIP System is available in a range of configurations to match your facility’s needs, allowing for tailored cleaning and future expansion:

Advanced solutions with recovery and reuse capabilities for high-volume, hygiene-critical operations.

Compact, portable solution designed for smaller operations and flexible cleaning needs.

Scalable, flexible, and quick to install, ideal for evolving process environments.

Our Modular CIP System is available in a range of configurations to match your facility’s needs, allowing for tailored cleaning and future expansion:

The system features configurable tanks, Tapflo Centrifugal Pumps, Cipriani Harrison butterfly valves, heat exchangers, flow meters, and sensors for temperature and conductivity. It also includes PLC controls, remote connectivity, and durable stainless steel construction designed for hygienic use.

For more information on CIP, please refer to some of our guides below.

Integrated flow meters, temperature and conductivity sensors, and heat exchangers allow for real-time monitoring and control of key cleaning parameters. The PLC interface lets operators adjust time, flow, and concentration settings for repeatable, high-performance cleaning cycles.

For more information on CIP, please refer to some of our guides below.

All wetted components are made from FDA-compliant 316 stainless steel for optimal hygiene and corrosion resistance. The full unit features washdown-rated parts and a durable 304/316 stainless steel frame for long-term reliability in demanding environments.

For more information on CIP, please refer to some of our guides below.

Yes! The pre-assembled design minimises installation time and operational disruption. It’s built for seamless integration, even in space-constrained environments, and offers adjustable feet for levelling on uneven surfaces.

For more information on CIP, please refer to some of our guides below.

Choose from 2-tank, 3-tank, or compact 3-tank square setups. Pipework is available in 2″ standard or 3″ custom sizing. Add-ons include electric heating, automated chemical dosing, and Ethernet connectivity.

For more information on CIP, please refer to some of our guides below.

Absolutely. The system supports FDA, HACCP, and cGMP compliance with built-in data logging, traceability, and secure remote access for diagnostics and validation.

For more information on CIP, please refer to some of our guides below.

It’s ideal for food and beverage, healthcare, cosmetics, and brewing. The system is customisable to meet the specific cleaning requirements of tanks, pipelines, and process equipment across these sectors.

For more information on CIP, please refer to some of our guides below.

Ready to streamline your cleaning? Speak to our team to explore a system built around your needs.