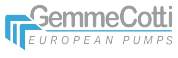

Vertical Immersion Centrifugal Pump Installation

Tapflo’s CTV Pump can be installed as a Flooded installation (left image) or as a Suction Lift installation with Suction Extension (right image)

Important Levels & Dimensions

| Detail | PP & PVDF | SS 316L | Comment |

| H min, mm | 50 | 80 | Distance between base plate and liquid level |

| MIN start, mm | 170 | 170 | Minimum level during start-up |

| MIN, mm | 80 | 80 | Minimum level during operation |

| S min, mm | 50 | 50 | Min distance to bottom of sump/tank |

| E max @ 25ºC, mm | 1000 | 1000 | Max length of suction extension |

| E max @ 40ºC, mm | 500 | 500 | Max length of suction extension |

| E max @ 60ºC, mm | – | – | Impeller must always be submerged |

Required for all installations

- Valve for Flow Control

- Non Return / Check Valve on discharge as close to the pump discharge as possible.

- Connection point for Pressure Gauge or Pressure Switch

- 45º joint for diverting discharge to enable more space when lifting the pump out of the sump/tank.

- Quick-release connection (e.g. CAM Lock) between the pump and piping system for easy disconnection during maintenance and removal of the pump.

- Arrange for drainage of liquid from the baseplate back into the sump/tank

Flooded Installation

- Suction Strainer w/ 3-5 mm Mesh if there are solids present in the fluid or the sump/tank is open to the atmosphere

Suction Lift Installation w/ Suction Extension

- A suction extension is required and the ID needs to correspond with the pump connection size. Do NOT use complex piping on the suction side. In certain instances a bottom valve (ball type) may be used, contact us for details.

Notes on instrumentation In order to ensure proper control of the performance and the conditions of the installed pump, we recommend using a pressure gauge on the discharge piping. It must always be installed between the pump and the shut off / regulating valve. The output can be read in Bar and translated into meters head and then compared to the performance curve of the pump to ensure that the pump is working “on the curve”.