What is a Pulsation Dampener?

A Pulsation Dampener is an inline dampening device used to smooth out pulsations in a pump’s output. They are used alongside a pump as a mounted accessory to help achieve certain flow rates for an application. They can be used with a variety of Positive Displacement Pumps which typically generate a pulsed flow (Diaphragm Pumps, Peristaltic Pumps, Dosing Pumps, Piston Pumps etc)

What Applications will I need a Pulsation Dampener for?

Pulsation Dampeners are required in some process applications when the customer needs smooth flow into the next phase of the production line, for example, to get an accurate reading through a flow meter or to fill a hopper consistently. On the flip side, Dampeners can be used to reduce water hammer effects through pipework. Water hammer is where the pump causes the pipes to vibrate and potentially fail, a smooth flow from a Pulsation Dampener reduces this.

For example, Diaphragm Pumps inherently produce a very turbulent discharge flow meaning that in some instances a Pulsation Dampeners are required to give a smooth pulse-free flow.

In the Tapflo UK range, we focus on Pulsation Dampeners for Diaphragm and Peristaltic Pumps, although we can also supply them for other pump technologies.

Types of Pulsation Dampeners

There are two main different types of pump pulsation dampeners available on the market:

- Active Pulsation Dampener

- In-line Passive Pulsation Dampener

An active pulsation dampener works by adjusting its output based on pressure and airflow changes made by the Diaphragm Pump. Whereas a

passive Pulsation Dampener requires the operator to pre-charge it to work in line with the pump’s air pressure. When the pressure changes, passive Pulsation Dampeners will require their operator to pre-charge them again to suit the new pressure.

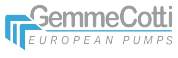

Tapflo’s DT Active Pulsation Dampener makes the process simpler and more efficient for operators but do require an active air supply to operate.

How does an Active Pulsation Dampener Work?

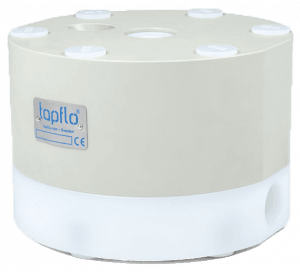

The Active Pulsation Dampener works by supplying an equal pressure to the pulsation supplied by the pump. The Dampener supplies this pressure during the low-pressure points of the pump’s operation, as the pressure drops between pump strokes creating a pulsating flow. The pressure supplied by the dampener decreases pressure variations, therefore producing a steady flow from your Diaphragm Pump. You can see the pressure drops and Pulsation Dampener benefits in action in the diagram below.

What are the Benefits of using an Active Pulsation Dampener?

- Extends pump life

- Minimize water hammer effects and vibration

- Reduces pump maintenance costs

- Protect your pipe system

Pulsation Dampener Case Study

Tapflo supplied a 2” Air Operated Diaphragm Pump to a bleach factory, the customer used the T400 PTT for a couple of days and then called us to explain that the bleach line, running along the roof of his production facility, was shaking. Due to the nature of the product being pumped health and safety on site could not allow this to continue.

Solution

Product: DT400 PTT

Size: 2” inline active pulsation dampener

Materials: HDPE and PTFE wetted parts.

This smoothed out the flow of the pump almost 100% and stopped any vibration through the customer’s pipework – removing the health and safety risk.

Click here for information on our DT Pulsation Dampener Troubleshooting.

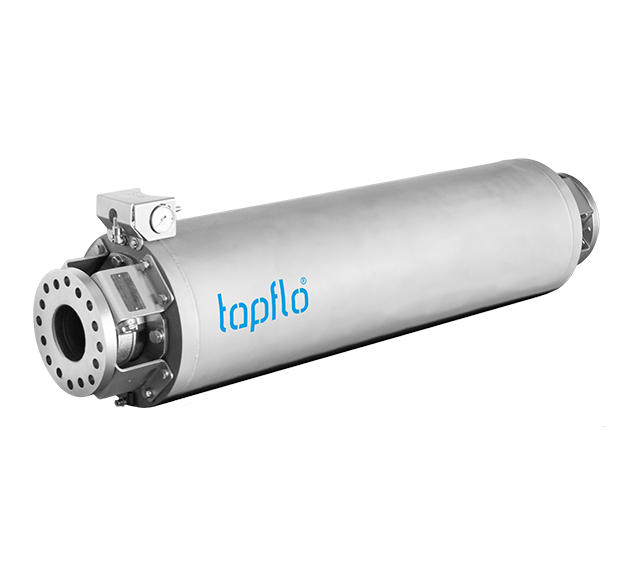

Peristaltic Pump Pulsation Dampener

To support our Peristaltic Pump customers, Tapflo offers an in-line Pulsation Dampener for our PT and PTL Series’. They can reduce the pulsation of your PT Pump by as much as 90% to reduce the vibration and water hammer effects on pipework. Another benefit of this accessory is its ability to be installed on-site horizontally or vertically for flexible installation.

You can find more information about the Peristaltic Pump Pulsation Dampener here.

If you’re looking to achieve a smoother flow from your pump, speak to a member of the Tapflo Sales Team today.