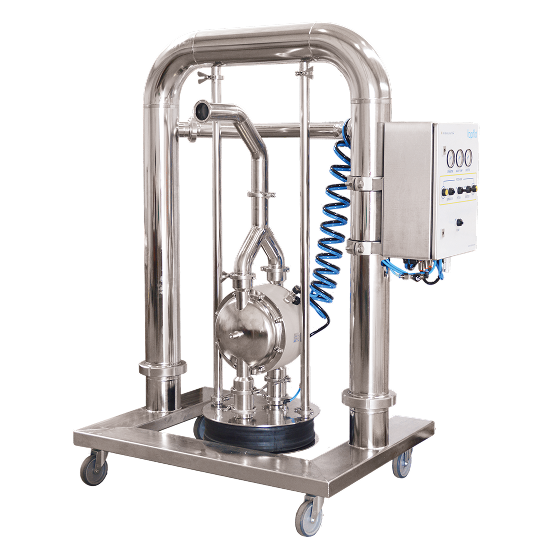

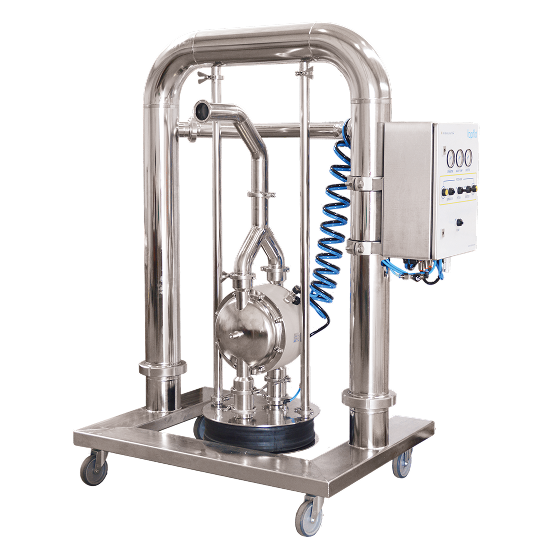

The HVS Drum Unloading System is designed for handling high-viscosity, paste-like substances that don’t flow easily. Equipped with a Sanitary Air-Operated Diaphragm Pump, this system ensures efficient emptying of barrels while boasting features such as being electropolished to Ra<1.6 as standard. With a volume per stroke of 2,300 ml and the ability to handle viscosities up to 20,000 cP, this ATEX-rated system accommodates solids passage of up to 15mm (with a ball valve) and 42mm (with a flap valve).

The HVS Drum Unloading System is designed for handling high-viscosity, paste-like substances that don’t flow easily. Equipped with a Sanitary Air-Operated Diaphragm Pump, this system ensures efficient emptying of barrels while boasting features such as being electropolished to Ra<1.6 as standard. With a volume per stroke of 2,300 ml and the ability to handle viscosities up to 20,000 cP, this ATEX-rated system accommodates solids passage of up to 15mm (with a ball valve) and 42mm (with a flap valve).

The HVS Drum Unloading System is designed for handling high-viscosity, paste-like substances that don’t flow easily. Equipped with a Sanitary Air-Operated Diaphragm Pump, this system ensures efficient emptying of barrels while boasting features such as being electropolished to Ra<1.6 as standard. With a volume per stroke of 2,300 ml and the ability to handle viscosities up to 20,000 cP, this ATEX-rated system accommodates solids passage of up to 15mm (with a ball valve) and 42mm (with a flap valve).

Multi Tabs Component (this text will not be visible on the front end)

Benefits

Industries

Specs

Operating Principle

Drums & Containers

Variations

Achieve a flow rate of up to 400 l/min, depending on the liquid properties and discharge pressures.

We manufacture our control panels in-house, offering you the flexibility to customise each Drum Unloading System to your specific needs.

By automating the unloading process, it significantly reduces processing times compared to manual emptying.

Impressive removal rate, removing up to 99% of the product from the drum.

Suitable for a variety of duties in Industrial and Hygienic installations (FDA, EN 10204 compliant).

Optional back-up diaphragm system with rupture detection, preventing cross-contamination of the process fluid.

| Technical Data | Specification |

|---|---|

| Max Flow (l/min) | 590 l/min |

| Displacement (ml/stroke) | 2300 ml/stroke |

| Max Discharge Pressure (Bar) | 8 Bar |

| Max Air Pressure (Bar) | 8 Bar |

| Max Viscosity | Up to 20,000 cP |

| Max Solids Passage (mm) | 15 mm (Ball Valve) & 42 mm (Flap Valve) |

| Max Temperature (°C) | 90°C for EPDM | 70°C for NBR | 110°C for PTFE |

| Weight (kg) | 190kg |

| Pump Body (W) | AISI 316L; electro polished | sandblasted |

| Wetted Metal | Surfaces Roughness | Ra < 1.6 (standard) | Ra < 0.8 | Ra< 0.5 |

| Sealings (W) | PTFE | EPDM | Silicon |

| Centre Block (NW) | PP |

| Diaphragms (W) | PTFE | EPDM | white EPDM | NBR* | white NBR |

| Valve Balls (W) | PTFE | AISI 316 | Ceramic* | EPDM* | NBR* | PU* |

| Air Valve (NW) | Body: Brass (std.) | AISI 316L | PET | O-rings: NBR (std.) | EPDM | FKM |

| Fasteners (NW) | A4-80 |

| Standard Connection | Tri-clamp DN65 ISO 2037 |

*Not intended for food-contact

| Drum Type | Details |

|---|---|

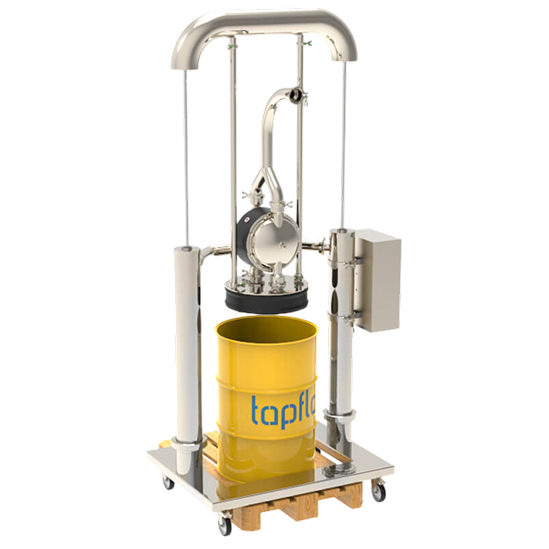

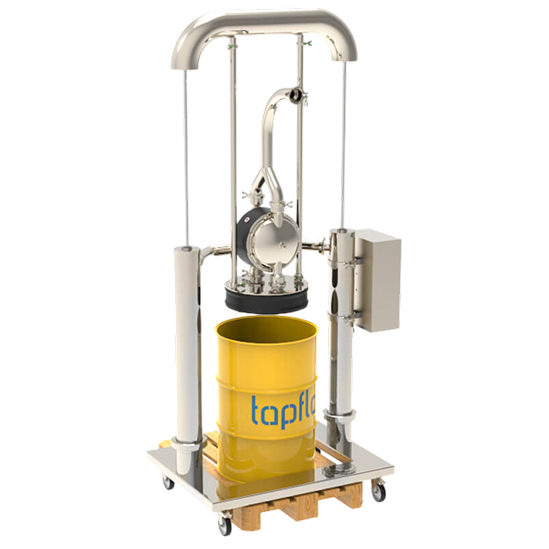

| Straight Drums: | The 200-litre straight steel drum stands out as the most common and available choice. For efficient handling |

| Conical Drums: | These containers offer exceptional space-saving capabilities by nesting together when empty. This design not only optimises storage efficiency but also ensures a clutter-free workspace. |

| Drum solutions tailored to your needs: | Our High Viscosity System (HVS) is expertly adaptable, the system is specifically designed for drum unloading systems handling viscous liquids. |

| IBC, Goodpack, and Bag-in-Box® Options: | Our HVS systems can also be configured to unload IBC containers, Goodpack multimodal containers, or Bag-in-Box® containers. |

Designed for high-volume operations (400 l/min), with integrated control panel with manual/automatic modes.

Ideal for 200L drums, IBCs & containers up to 100,000 cPs, featuring a Hygienic Progressive Cavity Pump for gentle transfer.

The HVS is specifically designed for unloading and handling high-viscosity, paste-like substances that do not flow easily.

It uses a Sanitary Air-Operated Diaphragm Pump.

Up to 590 l/min, depending on the model and application.

Surfaces can be sandblasted or electropolished, with roughness values of Ra < 1.6 (standard), Ra < 0.8, or Ra < 0.5.

Yes, it can be configured for IBCs, Goodpack, and Bag-in-Box® containers.

Pump body: AISI 316L (electropolished or sandblasted)

Centre block: PP

Diaphragms: PTFE, EPDM, white EPDM, NBR*, white NBR

Valve balls: PTFE, AISI 316, Ceramic*, EPDM*, NBR*, PU*

Air valve body: Brass (standard), AISI 316L, PET

O-rings: NBR (standard), EPDM, FKM

*Note: Some materials are not intended for food-contact.

Yes, our Unloading System is electrically and pneumatically operated, with pneumatic pumps and articulation, with electro-pneumatic control panels.