Our Modular Clean in Place (CIP) System offers a versatile and efficient cleaning solution for industries with varied cleaning requirements. Designed for flexibility, this pre-assembled system minimises downtime, reduces installation complexity, and ensures consistent cleaning performance across diverse applications.

Overview

Advantages of the System

Specifications

System Considerations

Options & Variations

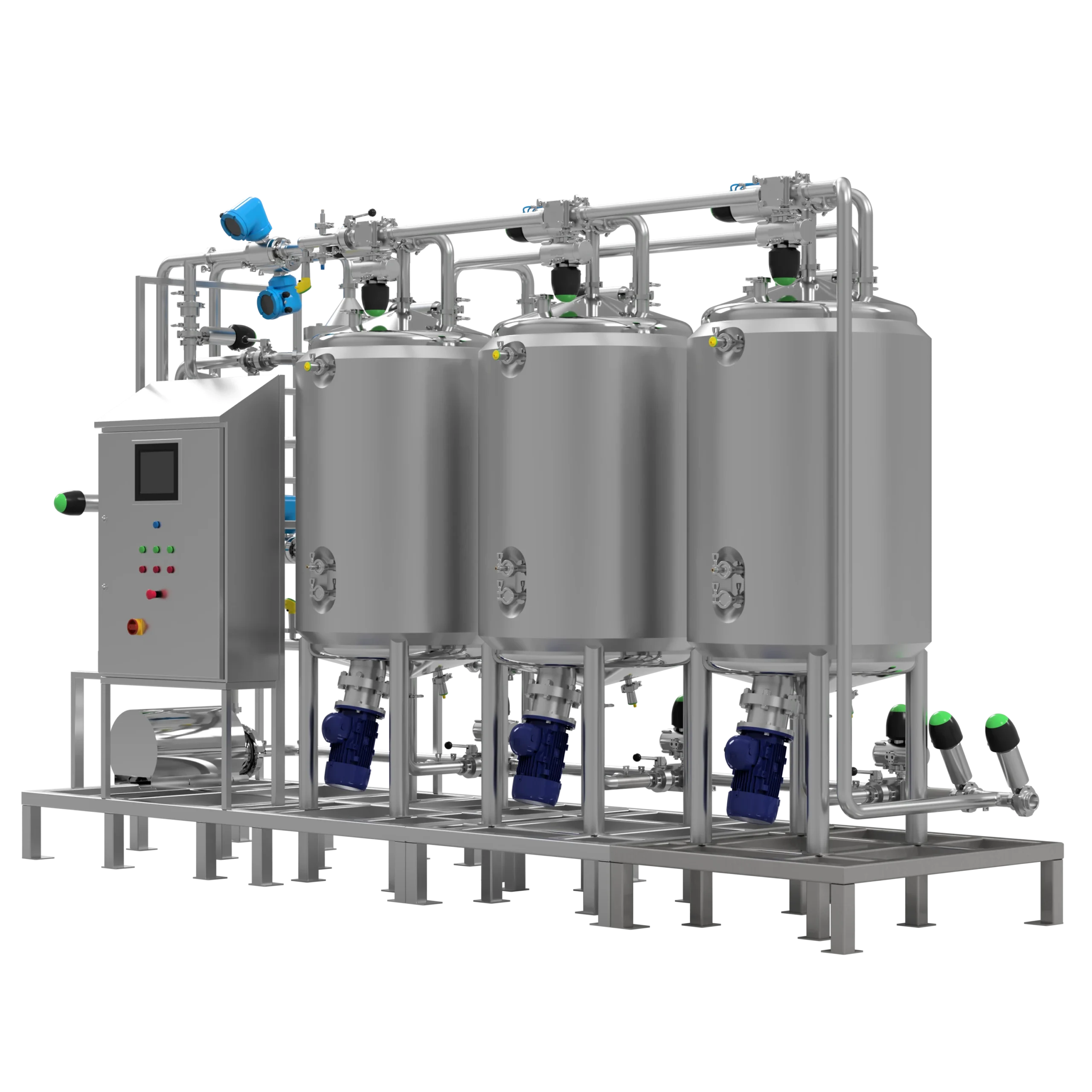

Our Modular CIP System is constructed off-site as a complete, ready-to-install unit that integrates seamlessly with existing process layouts. It incorporates key components such as tanks, pumps, heat exchangers, and control systems to deliver precise cleaning cycles. With adjustable parameters for flow, temperature, and cleaning agent concentrations, the system ensures repeatable cleaning results and meets rigorous regulatory standards.

- Rapid Installation: Modular construction minimises downtime by reducing the need for on-site fabrication

- Flexibility: Scalable and adaptable to various plant configurations and cleaning requirements

- Automation: PLC-controlled system with automated cleaning programs minimises human intervention and reduces operational errors

- Data Monitoring: Integrated data tracking for quality assurance and compliance with industry regulations

- Energy Efficiency: Optimised cleaning processes reduce water, chemical, and energy consumption

- Hygienic Design: Constructed with food-grade Stainless Steel (304/316) for corrosion resistance and ease of cleaning

| Technical Data |

Specification |

| Components |

Tanks, Centrifugal Pumps, heat exchangers, flow meters, conductivity sensors & temperature sensors |

| Cycle Types |

Supports alkali, acid, rinse & air purge cycles with customisable time, flow & concentration settings |

| Capacity |

Scalable for small to large facilities, with tank sizes & pump capacities tailored to customer requirements |

| Automation |

Features a user-friendly PLC interface for programming & monitoring cleaning cycles |

| Temperature Range |

Operates effectively up to 90°C for caustic cleaning |

| Material |

Constructed using FDA-compliant Stainless Steel (304/316), ensuring durability & sanitation |

- Space Optimisation: Modular designs are ideal for facilities with space constraints, as they can be positioned efficiently within existing layouts

- Ease of Maintenance: Pre-assembled systems simplify service and reduce maintenance downtime

- Scalability: The system can be expanded or modified as production demands grow

- Regulatory Compliance: Engineered to meet industry standards such as FDA, HACCP, and cGMP

- Industry-Specific Adaptability: Whether cleaning brewing tanks, cosmetic emulsifiers, or healthcare equipment, the modular system is customised to meet process-specific needs

Our Modular CIP System strikes a balance between operational efficiency, cost-effectiveness, and adaptability. By delivering pre-assembled, plug-and-play systems that maintain high cleaning standards, this solution is perfect for facilities looking for rapid deployment, repeatable cleaning performance, and long-term reliability.

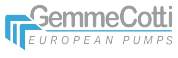

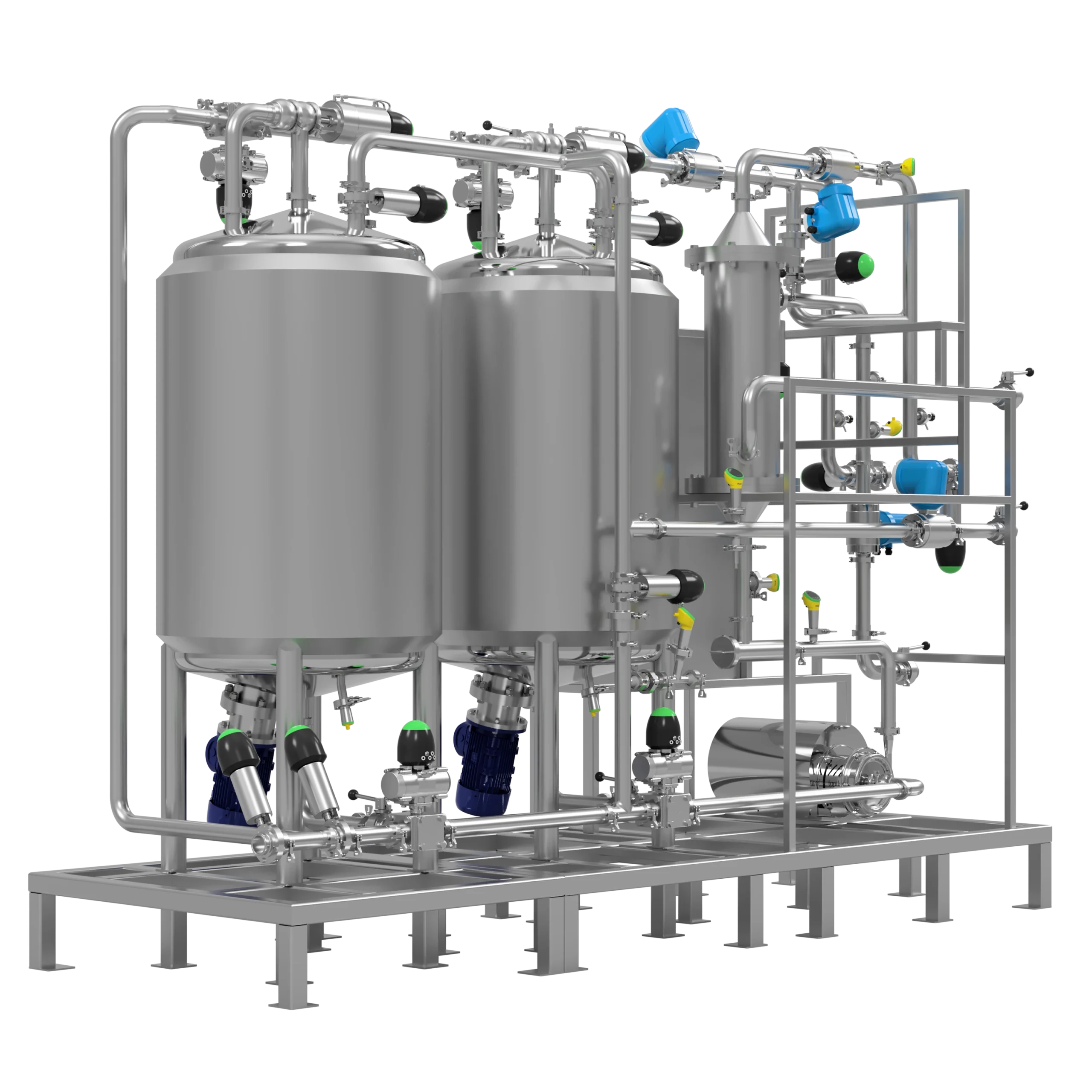

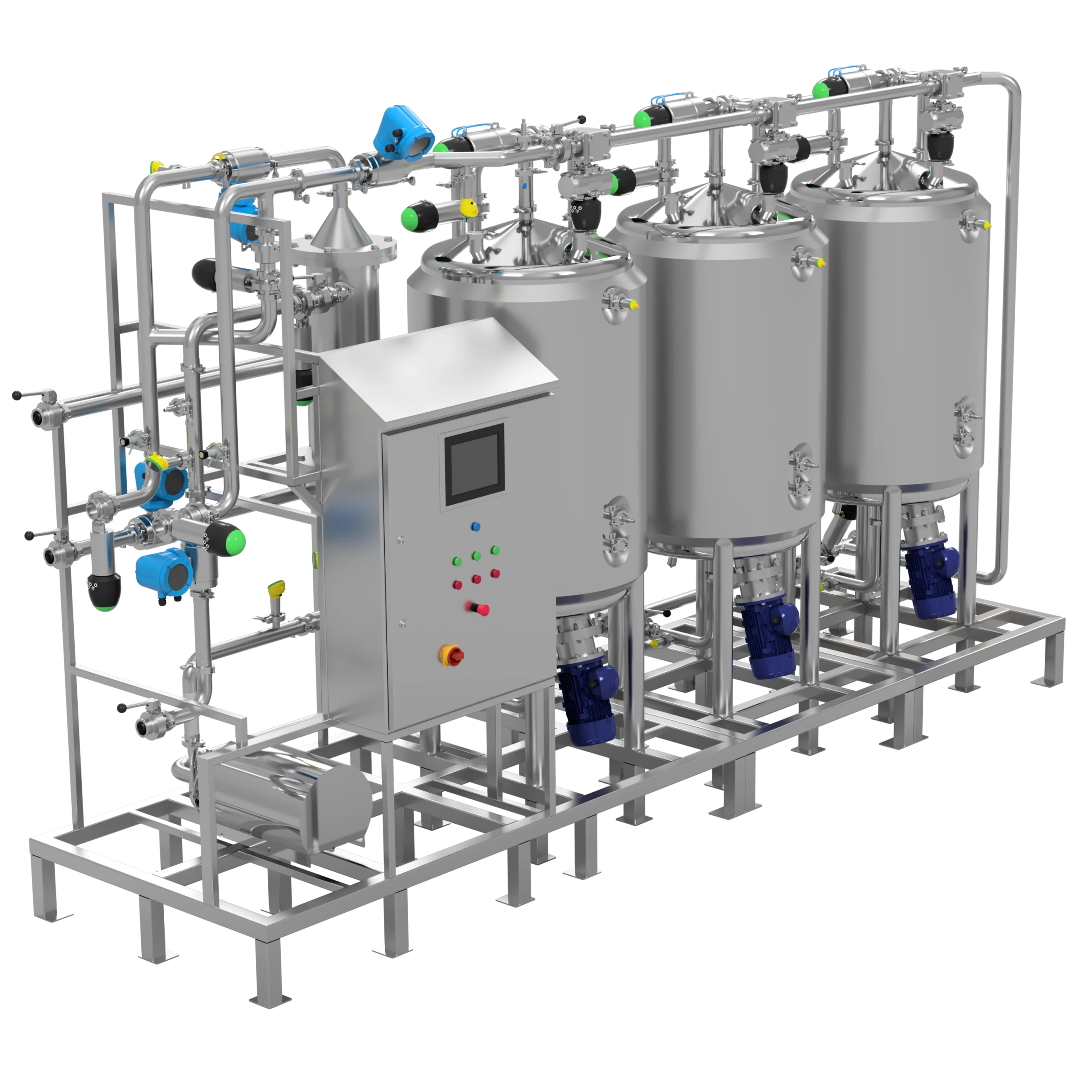

Our Modular CIP Systems are offered in multiple configurations to meet diverse operational requirements:

2-Tank System:

Ideal for smaller setups or plants with basic cleaning requirements. Features separate tanks for cleaning agents and rinse water, ensuring efficient cycles.

3-Tank System:

Designed for operations requiring alkali, acid, and rinse cycles. Provides greater flexibility for multi-stage cleaning processes.

3-Tank Square System:

A compact alternative to the standard 3-tank system optimised for facilities with space constraints. Maintains full functionality with a smaller footprint.