A leading choice in today’s market, Tapflo Diaphragm Pumps use no-nut, clean-face diaphragms, with 70% fewer parts than other AODs. With the ability to self-prime & handle corrosive, abrasive & viscous fluids, these pumps can run dry without damage, and operate without glands/seals, reducing overall wear.

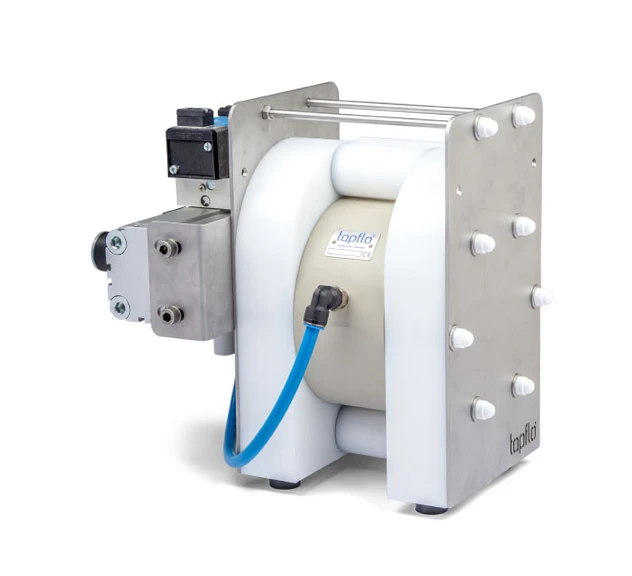

HDPE & PTFE Air Operated Diaphragm Pump

ATEX Metal Diaphragm Pump

Metal Diaphragm Pump

Sanitary Diaphragm Pump

ATEX HDPE/PTFE Diaphragm Pump

Powder Pump

Barrier Diaphragm Pump

Aseptic EHEDG Diaphragm Pump

Pharmaceutical Pump

Diaphragm Drum Pump

Low Energy Air Pump

Low Energy Air Pump – Sanitary

Filter Press Diaphragm Pump

Electric Diaphragm Pump

Pulsation Dampeners for Diaphragm Pumps

Wall Mount Decanting Units

Insulating Covers for Diaphragm Pumps