EUROPE

ASIA & PACIFIC

Filter Results

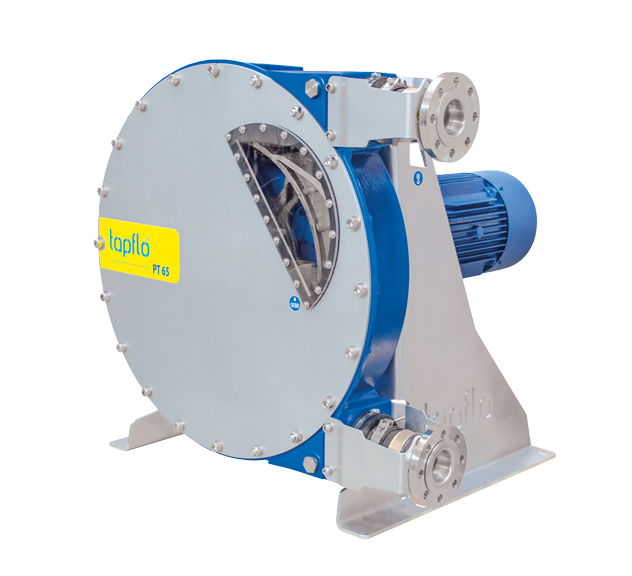

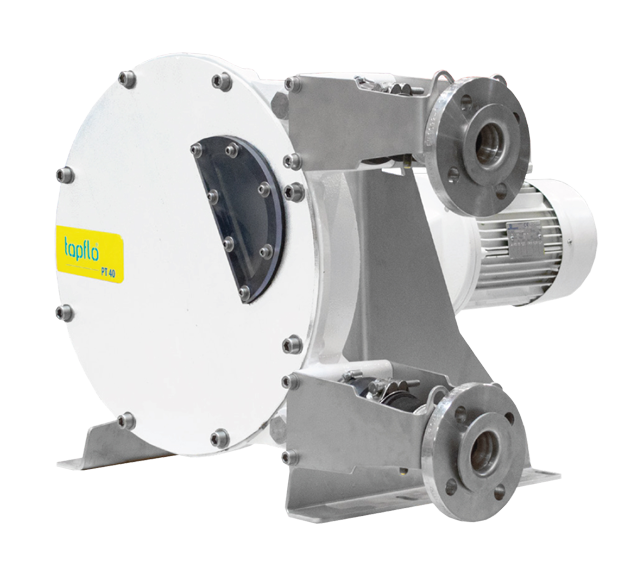

Peristaltic Pumps, also known as Hose Pumps, are a type of Positive Displacement Pump that uses a hose to transfer the fluid, meaning no other part of the pump is in contact with the media. They are highly versatile with both high and low-pressure options and the ability to self-prime up to 9m.

Centrifugal Pumps are highly versatile and can be easily modified to suit your requirements. Some of the key features of Centrifugal are:

Peristaltic Pumps can be used for a wide range of applications, specifically those containing solids as the hose maintains shape, protecting the media within the pump.

To choose the appropriate Peristaltic Pump for your application, ask yourself the following questions:

Some of our materials offer an ATEX option on request for explosive applications and environments.

Regular maintenance is crucial to keeping your pump performing at its best and ensuring a long life span. Peristaltic Pumps are simple to look after, the key maintenance is down to taking care of the hose.

Depending on the size of your pump and the fluid you are pumping, a more detailed maintenance schedule may be required.

Will your pump be stationary, or do you need it to be portable? If you require portability, Peristaltic Pumps can be fitted to trolleys of any size to suit your needs.

Will you require additional accessories for your pump? Pulsation dampeners to reduce pulsation and vibration within your piping system, and assemblies and fittings for your hoses are available for Peristaltic Pumps.

Max. Flow:

100m³/hr

Max. Head:

150m

Max. Temp:

80°C

Material:

Nodular Cast Iron

Max. Flow:

10m³/hr

Max. Head:

40m

Max. Temp:

80°C

Material:

Metal

Max. Flow:

12m³/hr

Max. Head:

150m

Max. Temp:

80°C

Material:

Metal

Max. Flow:

N/A

Max. Head:

N/A

Max. Temp:

80°C

Material:

Metal

Tapflo UK is pleased to supply a range of Hose assemblies and fittings to support the operation of your Peristaltic...

Tapflo UK is pleased to supply a range of Hose assemblies and fittings...

Our friendly team at Tapflo UK would be more than happy to assist you further with any pump solutions, delivery information or questions you have. If you need additional support on-site, you can speak to a member of the team today to organise a site visit.

Give us a call now:

Search our pump support articles: