EUROPE

ASIA & PACIFIC

Filter Results

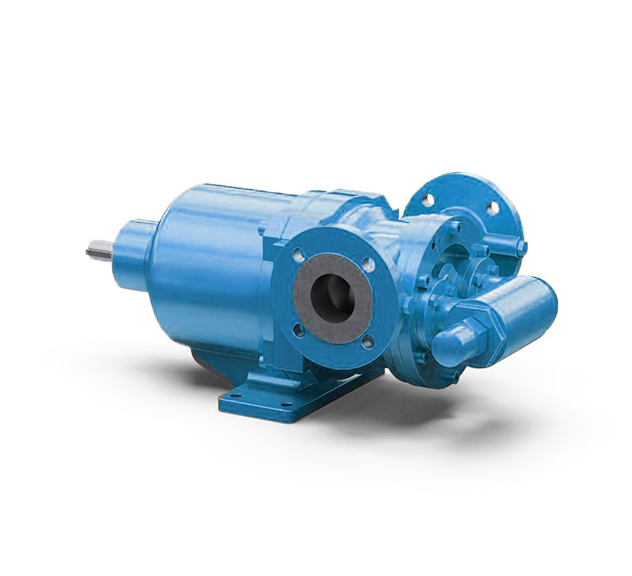

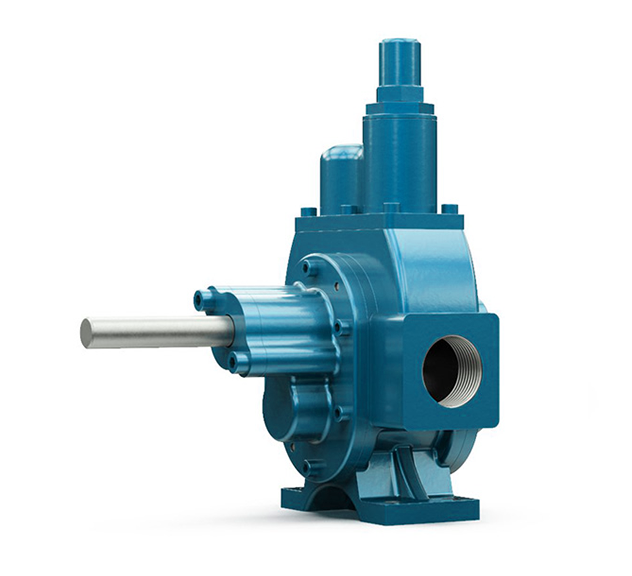

Gear Pumps are a type of Positive Displacement Pump available in two designs, internal and external gear. They work by enclosing a fixed volume of fluid using interlocking cogs or gears that create a continuous flow of fluid. The external design uses two identical gears rotating next to each other, supported by separate shafts, whereas the internal design consists of two gears of different sizes, with one rotating inside the other.

Gear Pumps provide numerous benefits and have been engineered to meet the highest safety standards, offering ATEX on request.

Gear Pumps are widely recognised for their exceptional fluid transfer capabilities and are well suited to the transfer of viscous and semi-viscous fluids.

To choose the appropriate Gear Pump for your application, ask yourself the following questions:

Gears are available in various materials to support your application requirements.

Some of our materials offer an ATEX option on request for explosive applications and environments.

Regular maintenance is crucial to keeping your pump performing at its best and ensuring a long life span. To look after your Gear Pump, you should:

Depending on the size of your pump and the fluid you are pumping, a more detailed maintenance schedule may be required.

Will your pump be stationary, or do you need it to be portable? If you require portability, Gear Pumps can be fitted to trolleys of any size to suit your needs.

Max. Flow:

55m³/hr

Max. Head:

120m

Max. Temp:

250°C

Material:

Metal

Max. Flow:

250m³/hr

Max. Head:

150m

Max. Temp:

200°C

Material:

Metal

Max. Flow:

7.7m³/hr

Max. Head:

300m

Max. Temp:

100°C

Material:

Metal

Max. Flow:

250m³/hr

Max. Head:

150m

Max. Temp:

200°C

Material:

Metal

Our friendly team at Tapflo UK would be more than happy to assist you further with any pump solutions, delivery information or questions you have. If you need additional support on-site, you can speak to a member of the team today to organise a site visit.

Give us a call now:

Search our pump support articles: