Twin Screw Pump

Screw Pumps have the same design principles as a positive displacement pump where a vacuum is created inside the pump to draw fluid out to the discharge side. They combine the features and benefits of a lobe, centrifugal and piston pump with their robustness and versatility for many applications and industries. This guide will help to provide some clarity on how screw pumps work, the advantages and disadvantages of screw pumps and the range we offer at Tapflo UK that can be supplied for your requirements.

How Screw Pumps Work

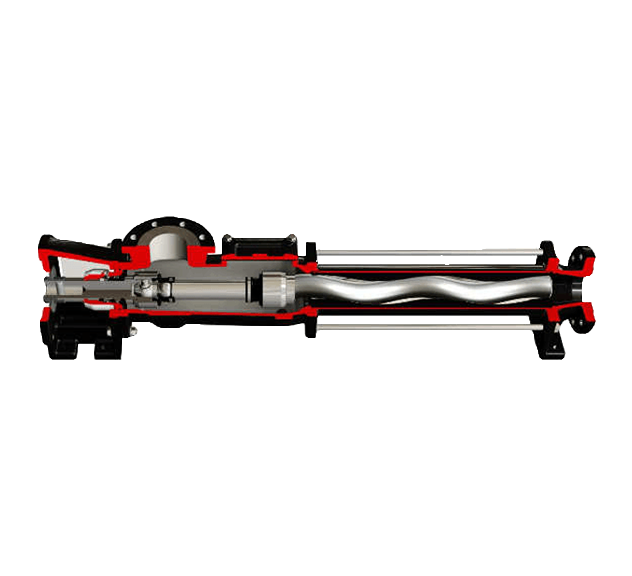

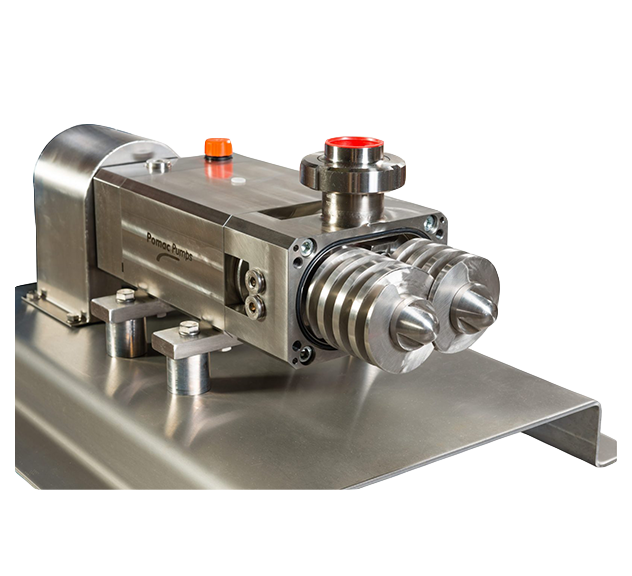

Screw Pumps work by using multiple screws as the key component to drive fluid through the pump. The screws rotate on an axis and create a positive displacement suction force to help push fluid from the pump inlet towards the outlet for it to be discharged. With a twin-screw pump, the volume between the screws increases as they counter-rotate and pass the suction port. This creates a vacuum that draws liquid into the suction port and the pump housing. As they continue to rotate past the discharge port, the volume between the screws decreases, causing pressure to build up, forcing the liquid out of the discharge port. Take a look below at our video featuring Luke, Tapflo UK’s Pump expert to find out more about how a twin screw pump works and the many benefits it has to offer!

Types of Screw Pumps

As mentioned previously, there are a few different types of screw pumps available on the market with different designs. Take a look below at the most common:

- Single Screw Pumps – These are actually known as Progressive Cavity Pumps. Although they are similar to screw pumps, they feature a rotor and stator that differ from the screw component found in screw pumps. If a progressive cavity pump sounds more like what you are looking for, take a look at the Nova Rotas Diamond series we offer at Tapflo.

- Twin Screw Pumps – also referred to as double screw pumps, are ideal for high head, high flow applications and in particular commonly used for transfer duties.

- Triple Screw Pumps – These screw pumps are typically used for smaller pumping systems such as lubrication operations. There is also the option of a four-screw pump which is the same as a twin-screw pump but is designed with four internal screw components per rotor for a higher flow rate.

Advantages of Screw Pumps

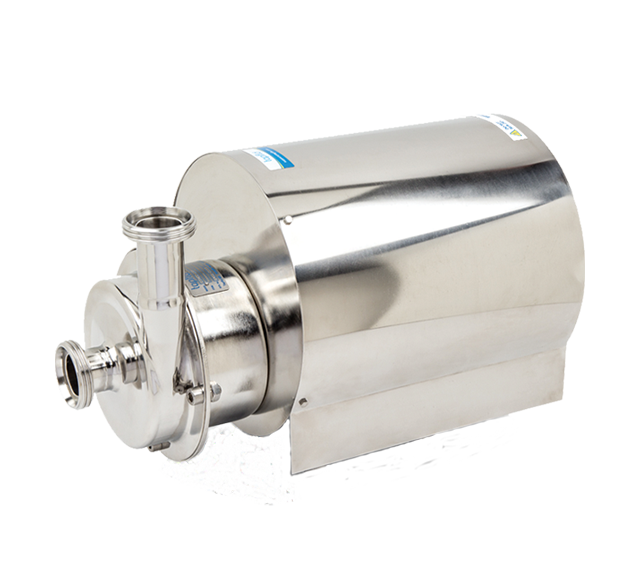

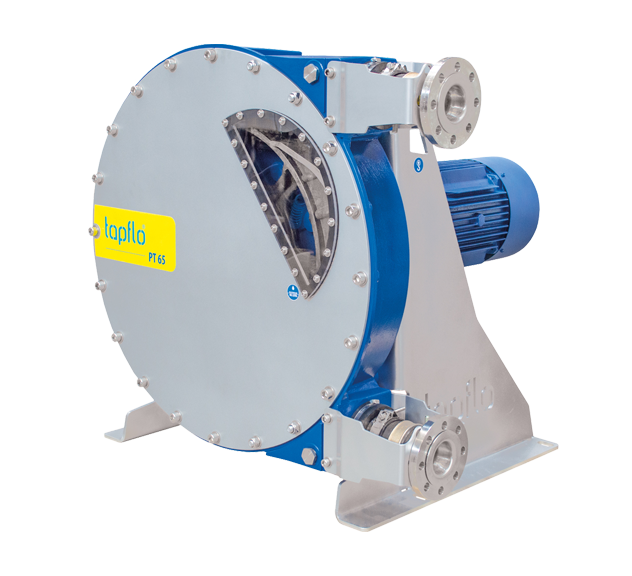

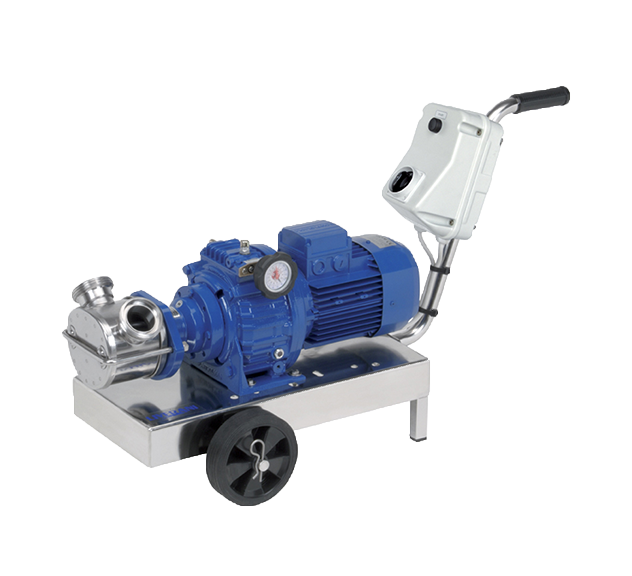

Screw Pumps are one of the most versatile pumping options on the market that can be used for a wide variety of flow rates and pressures. In partnership with Pomac Pumps, Tapflo UK supplies the Twin Screw Pump which has been designed for hygienic applications specifically to meet strict hygienic standards for food, pharmaceutical and cosmetic industries. It’s EHEDG (European Hygienic Engineering and Design Group) rated and is cast to high-grade stainless steel AISI 316L to keep bacteria to a minimum within the pump. Take a look below at just some of the advantages our screw pumps have to offer:

- Self-priming capabilities up to 8m

- Ability to dry run

- The screw design allows for solids up to a maximum of 40ml to be pumped

- Steady flow

- High head

- High flow

- High temperature, up to 140 degrees

- Speed range from 100 – 3600 rpm

- Can handle shear sensitive fluids

- Can reach up to 10000

Disadvantages of Screw Pumps

As with any product design, there are a few disadvantages that need to be considered when choosing the right pumping system for your business. Take a look at some for the screw pump below:

- Can be expensive, this is due to being manufactured with different rotating elements and high-quality materials to suit applications

- Not suitable for small pumping speeds below 100rpm

- Not suitable for highly viscous or abrasive fluids.

What is a Screw Pump Used for?

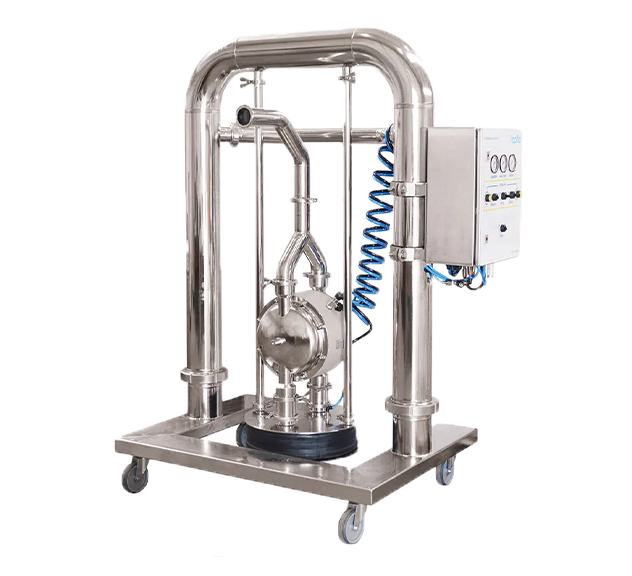

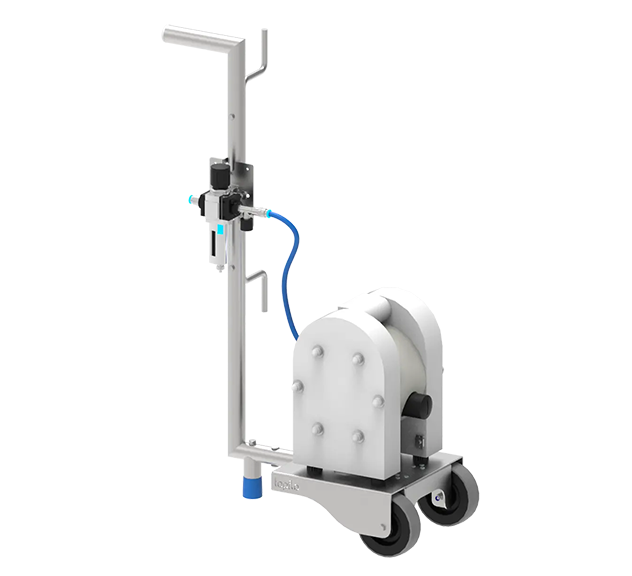

Screw Pumps have many applications they can be used for and are becoming the go-to solution for many businesses due to being so versatile for so many industries. They are ideal for viscous and shear sensitive products to ensure the product your pumping is not damaged during the pump’s operation. They also work well for the following applications, but are not exclusive to these:

- Suction

- Feeding

- Filling

- Displacement

- Supply

- Flush

- Dosing

- Loading, unloading

- CIP & SIP

If you’re in the market for a twin-screw pump for your application, contact Tapflo UK today for a competitive price and reliable pump solution.