High Viscosity Pump: Frequently asked questions

Pump applications come in a variety of thicknesses, textures and have varying durability. When choosing a high viscosity pump, it’s important to firstly recognise how your applications viscosity will impact the pump type and specifications you require.

Not only this but you will need a high quality pump system that is equipped with the correct accessories to ensure that the product being pumped doesn’t degrade in quality or change during the pumping process. There are a number of other factors to consider alongside this, but this guide will be focusing on viscosity. Our frequently asked questions are listed below to run you through what viscosity is and the different high viscosity pump options available.

What is ‘viscosity’?

High viscosity food application example

Viscosity is the thickness, stickiness and semi-fluid consistency of a product. For example, water would have a very, very low consistency whereas something like Vaseline would have a very high viscosity. Here at Tapflo, we use centipoise to measure the viscosity of a product, although there are other units of measurement used.

What pump type is best for high viscosity pump products?

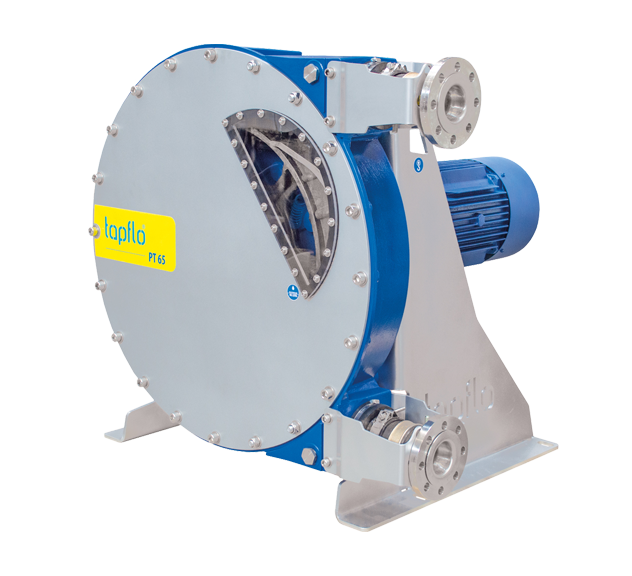

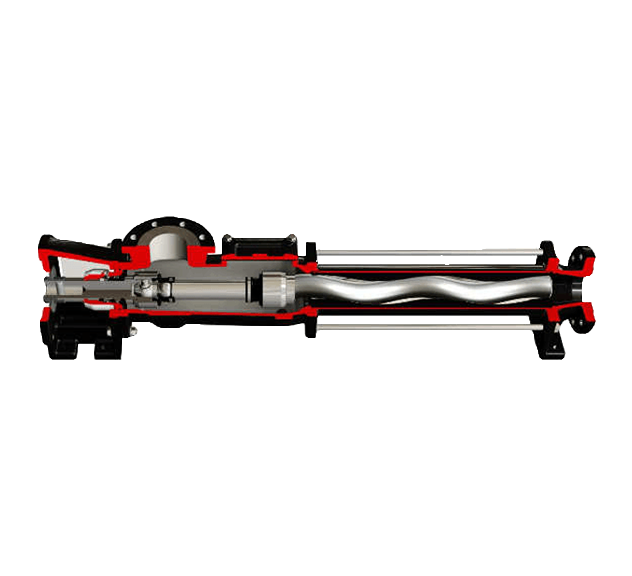

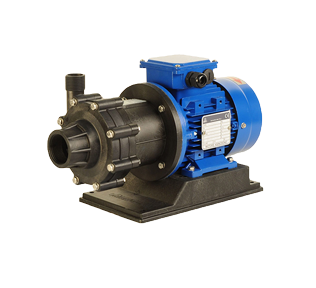

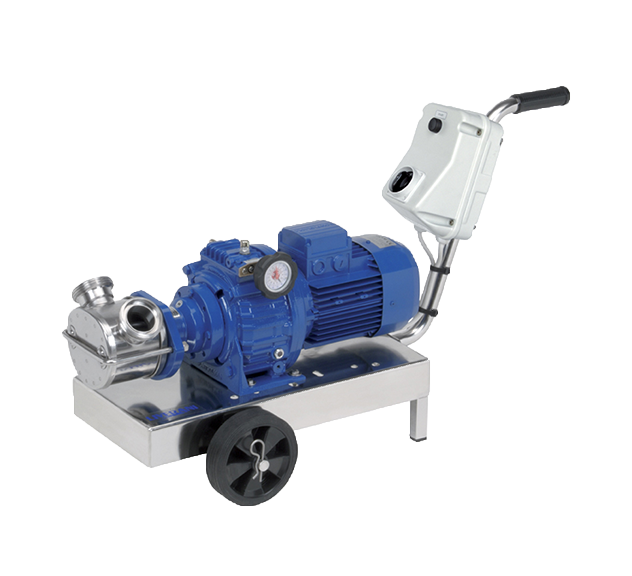

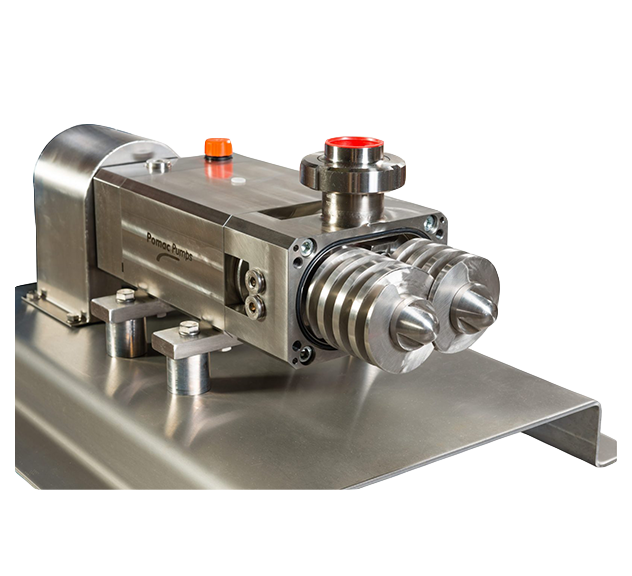

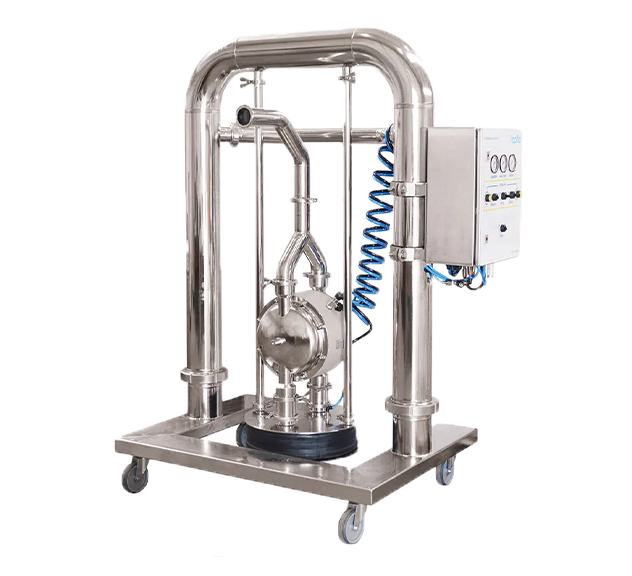

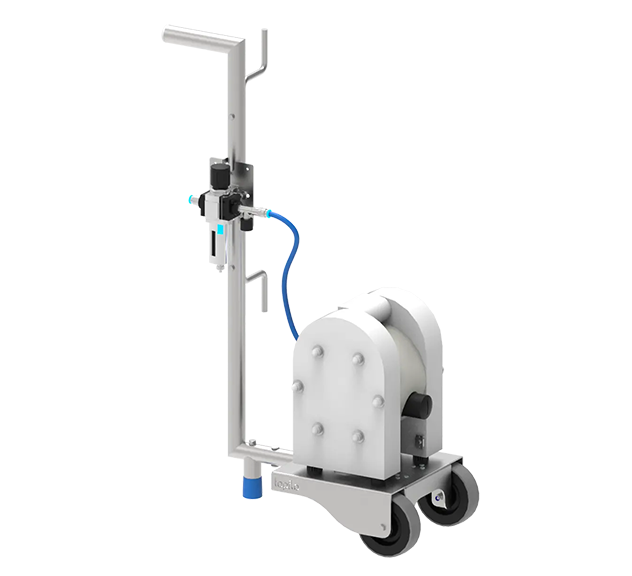

Depending on a number of factors in the process, Tapflo has a number of pumps suitable for highly viscous products. Our Diaphragm Pumps can support products up to about 10,000 cPs, whereas our Lobe and Twin Screw Pumps can support products of up to 1,000,000 cPs.

What is the most important thing to consider when specifying a pump for viscous products?

Selecting a pump for viscous products can be slightly challenging…for some people anyway! Not for the Tapflo team! It’s important to remember that priming a pump can be a difficult task with viscous products, especially if they are thick and sticky like golden syrup for example! It’s also important that flow rates will be dramatically less than shown on performance curves when pumping viscous products! Viscous products tend to get thinner and easier to move when they are heated, it’s important to state the temperature the product will be pumped at!

High Viscosity Pump Case Study

Tapflo were recently approached by a cheesecake Company. They needed a pump to cheesecake mix from large 500L mixers and deposit into a production line hopper. Take a look below at the pump solution we provided for them that would work ideally for the chosen pump application.

Application Details

| Fluid | Viscosity | Flow Rate | Temperature | Solids | Pipe Work | Length of discharge | Suction Condition | Pump Type provided | Material |

| Cheesecake mix containing honeycomb chunks | Approx. 200,000 cps | 200lpm | 2 degrees | Some 10mm chunks | 3 1/2” | 2m vertical 3M across | 1.5M | Twin Screw Pump

|

Stainless Steel |

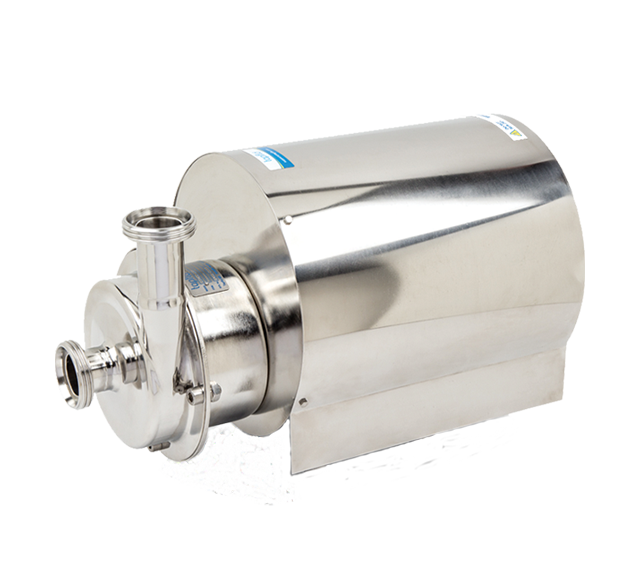

After trialling a few pumps the customer wanted a pump that would keep the marble effect of the cheesecake and not crush any of the solids in the mix. Tapflo’s sanitary twin-screw pump was perfect for this application as it is gentle on the product and can pump products of up to 1,000,000 cPs. The pump was installed and the customer was happy with the end result.

Got a similar application? Speak with our pump specialists to help you find a solution for your fluid handling.