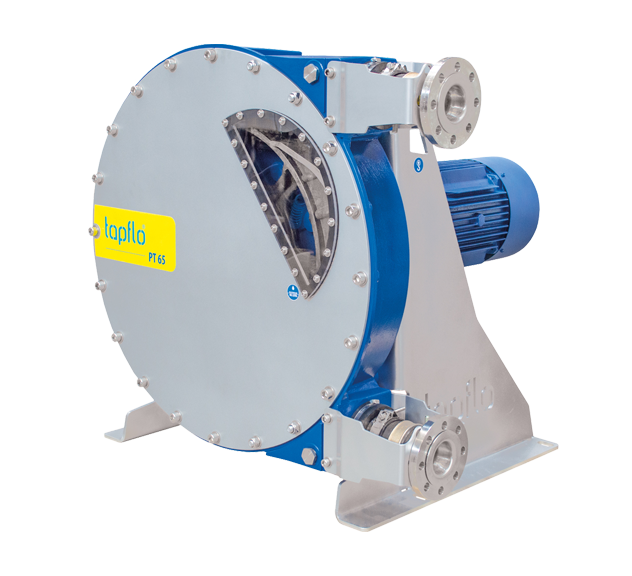

What is a Flexible Impeller Pump?

A Flexible Impeller Pump is a type of Positive Displacement Pump known for its versatile capabilities in handling fluids and solids in suspension. The impeller, made from rubber, and vanes in the pump’s housing work together to achieve a steady, pulseless flow without pressure spikes. This makes them highly suitable for a wide range of applications, especially in transferring, filling, emptying, recycling and mixing, filtering and separation as well as metering and dosing duties.

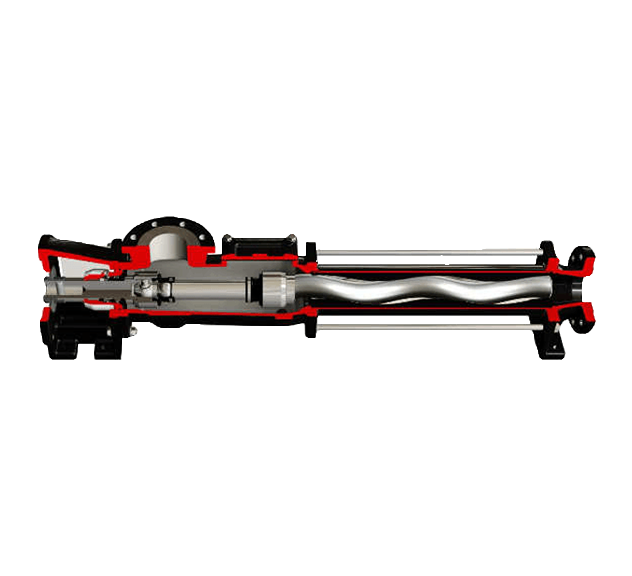

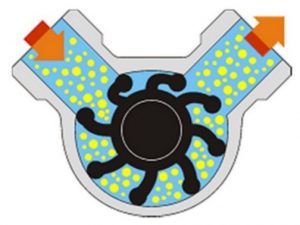

How Does a Flexible Impeller Pump Work?

The pump’s operation involves trapping a set amount of liquid at the inlet with the vanes, moving the fluid through the pump housing (positive displacement), and finally forcing it out of the discharge. The flexible vanes deform slightly during rotation, ensuring a smooth and pulse-free flow. This, coupled with high self-priming capability (up to 6m from dry), makes Flexible Impeller Pumps ideal for various applications.

Industries and Applications

| Industry | Product Applications |

| Oenological | Wine, musts and stemmed grapes |

| Food | Fruit pulp, juice, honey, syrups, milk, yoghurt, oil, brine and beer |

| Chemical | Ink, paint, detergents, water-based glue, starch, rubber latex and wax |

| Cosmetic and Pharmaceutical | Liquid soap, cream, shampoo and cleaning lotion |

Benefits of Using a Flexible Impeller Pump

Customisability:

- Each Flexible Impeller Pump can be tailored to specific operational requirements

- Customisation options include configuration, impeller material and additional features like Geared Motors, Trolley Mounting or Hydraulic Drives

Shear-Sensitive Handling:

- Ideal for shear-sensitive viscous products and those with solids in suspension

- Handles up to 50,000 cPs and solids passage capability up to 25mm

Reversible Operation:

- Pump head can operate bi-directionally for cleaning and refilling purposes

- Pump head’s rotation can be changed into 5 different positions, allowing installation in various pipework configurations

Self-Priming Capability:

- Self-primes up to 6m from dry, suitable for emptying sumps, tanks, drums and IBCs

Pulse-Free Flow:

- Produces a steady flow, making it ideal for filling, dosing and filtration applications

Impeller Material Options

We have a range of impeller material options available to suit your operational requirements:

| Impeller Material | Application |

| NBR | FDA-approved, superior resistance to oils and fats |

| CR | Best balance between chemical and mechanical resistance |

| EPDM | FDA-approved, ideal for hot fluids and CIP, excellent with acids and alkalis |

| NR | Highest mechanical resistance, suitable for water-based fluids at room temperature |

| VMQ | Suitable for high temperatures with low mechanical resistance |

Tapflo's Range of Flexible Impeller Pumps

Tapflo UK is proud to supply a wide range of pump systems as part of our partnership with Italian Pump Manufacturer, Liverani.

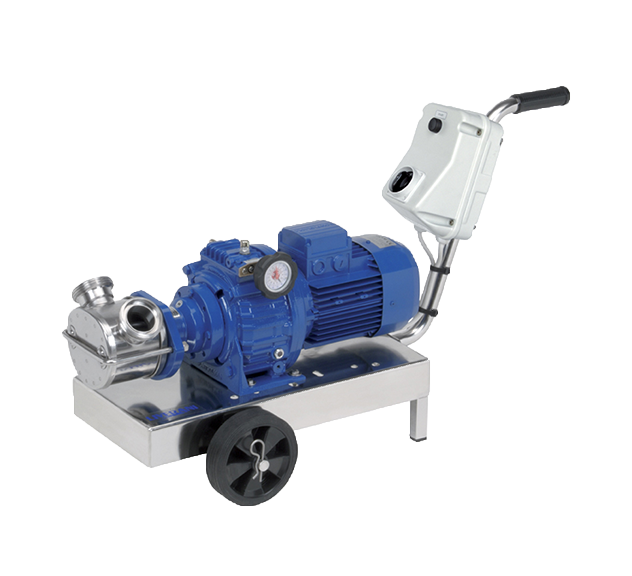

EP Self Priming Flexible Impeller Pump:

- Close-coupled design, on/off reversing switch

- Customisable design meaning it can be fitted onto a trolley system or fitted with carrying handles

- Self-priming up to 6m from dry, bi-directional operation

Read our dedicated Flexible Impeller Pump Article for more details on our Self-Priming Flexible Impeller Pump.

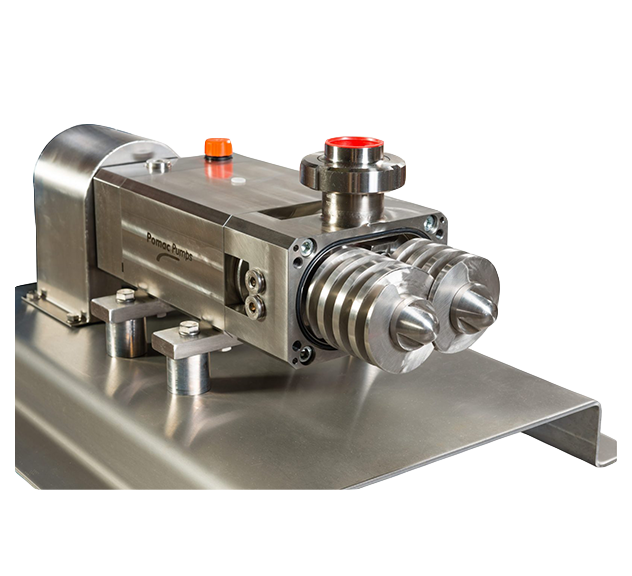

Bare Shaft And Hydraulically Driven Flexible Impeller Pump:

- Used for loading/offloading applications

- Lightweight and compact design, versatile port configuration

- Range of material options available

- Range of accessories available for a customised solution

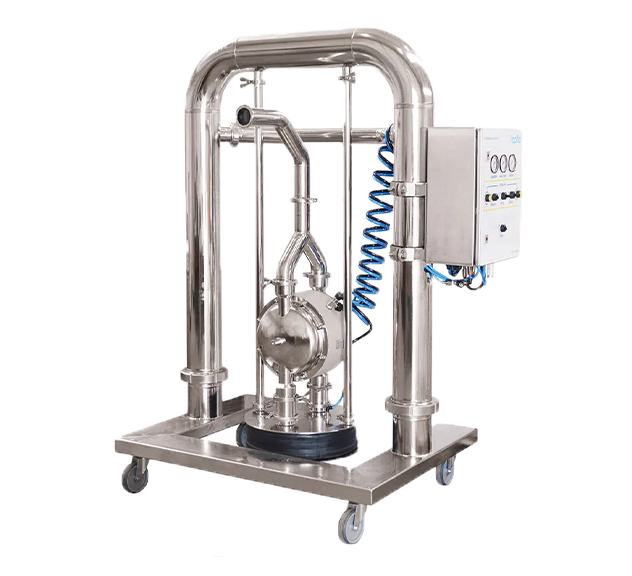

VA & INV Self Priming Flexible Impeller Pumps:

- Variable speed control with mechanical variator, accurate flow control with calibrated inverter panel

- Waterproof and floating bi-directional radio controller with a charging station in a 100m range

- Supplementary 4-20 mA connector

- Timing system

- 4-wheel trolley

- Manual or Spring-Loaded By-Passes available

All-in-One Flexible Impeller Pump:

- 7″ colour touch screen for data review, scheduling and analysis

- Remote control for speed variation, inversion rotation and start/stop

- High-precision magnetic Food-Grade flow meter

- Built onto Stainless Steel trolley with 2 fixed and 2 pivoting wheels

Inverter Drive Self Priming Flexible Impeller Pump:

- Designed for transfer of sensitive and delicate fluids

- Self-priming up to 6m, solids passage up to 25mm

- Manual or Spring-Loaded By-Passes available

Gearbox Drive Self Priming Flexible Impeller Pump:

- Close-coupled design to a geared motor, suitable for medium to high viscosity fluids up to 50,000 cPs

- Pulsation-free pumping, reversible operation

- Self-priming up to 25mm

- FDA-approved EPDM and NBR impellers available

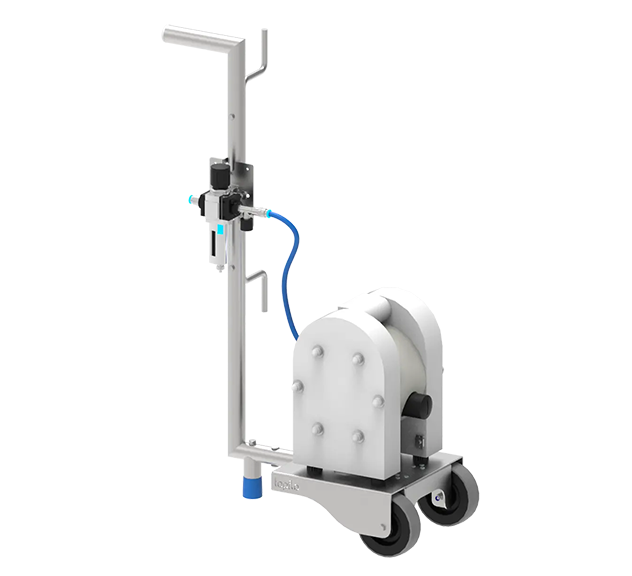

Miniverter Self Priming Flexible Impeller Pump:

- Characterised by close-coupled design, variable speed control

- Solids passage up to 5mm, suitable for solids handling

- Pulse-free flow

- Pump had can be installed and rotated in various positions

V-Belt Drive Self Priming Flexible Impeller Pump:

- Self-priming up to 6m, suitable for viscous fluids

- Max viscosity up to 50,000 cPs

- Pump heads constructed from Stainless-Steel 304

- Manual or Spring-Loaded By-Passes available

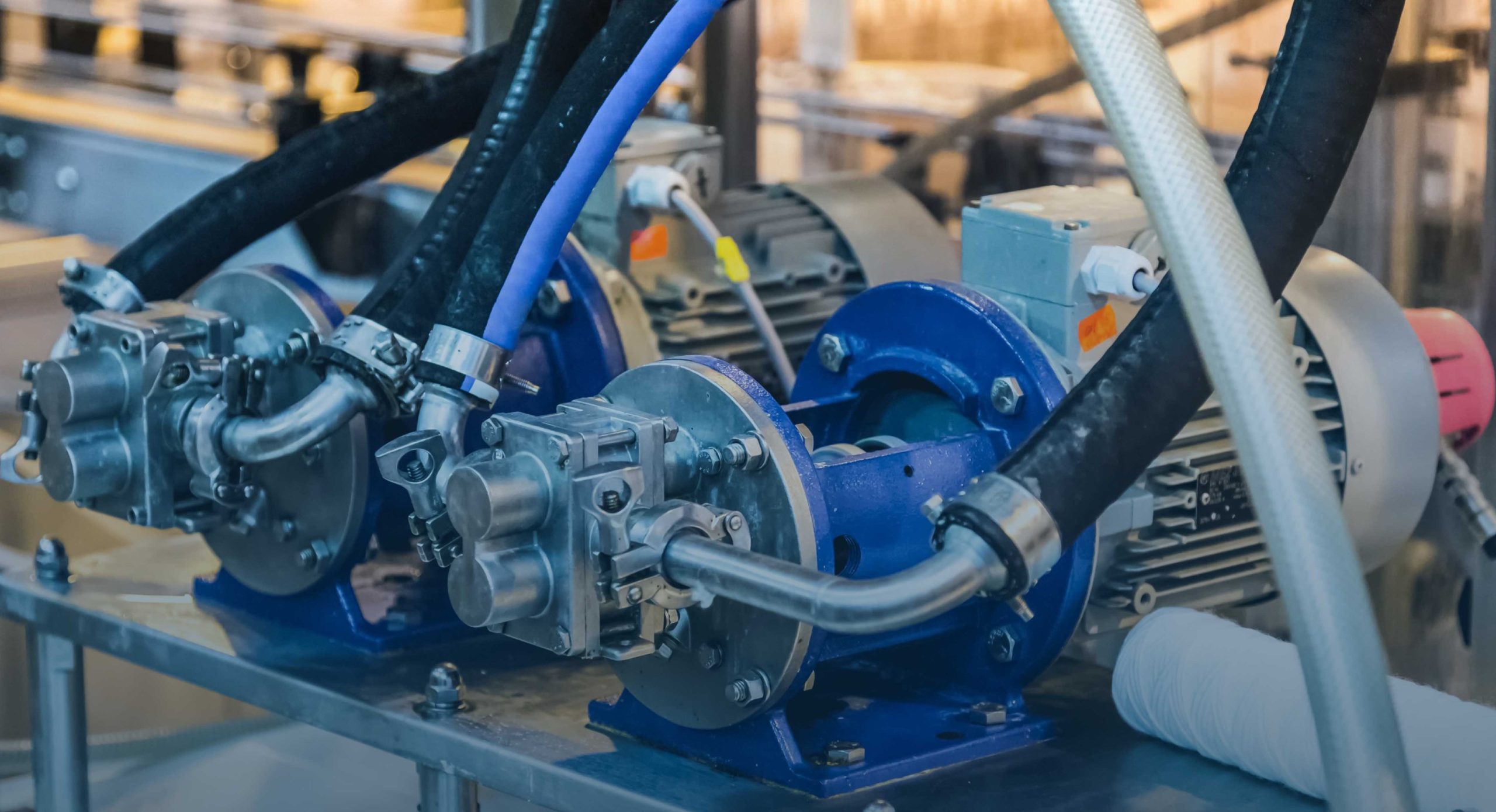

Discover the real-world impact of Flexible Impeller Pumps in action in our dedicated case study on a Flexible Impeller Pump Skid System we supplied to a Textile Manufacturer.

You can also take a look at our YouTube video where our Senior Sales Executive, Stephen Eastcott, shares his knowledge on the benefits and applications of Flexible Impeller Pumps:

Conclusion

In the Process industry, being efficient and adaptable is crucial. Flexible Impeller Pumps from Tapflo UK offer unparalleled versatility. Trust in Tapflo’s expertise as we continue to drive innovation in Industrial and Hygienic processes.