About the Chemical Industry

The Chemical Industry encompasses the synthesis, processing and transformation of raw materials into diverse chemical products. This expansive sector is categorised into various segments, including petrochemicals, agrochemicals, specialty chemicals and more. The production processes involved are often intricate, requiring precision and adherence to stringent safety standards.

Importance of Pumping in the Chemical Industry

- Material Transfer:

- Raw Material Intake: chemical plants rely on pumps to transfer raw materials, including liquids and gases, from storage tanks to the production units

- Processing Operations:

- Reaction Processes: our pumps facilitate the precise mixing of reactants during chemical reactions, ensuring uniformity and efficiency

- Temperature and Pressure Control: Chemical Pumps are critical in maintaining optimal temperature and pressure conditions during chemical processing

- Product Handling:

- Product Transfer: upon completion of chemical processes, pumps are vital for transferring finished products to storage tanks or packaging units

- Filtration and Separation: our pumps assist in filtration and separation processes, crucial for refining chemical products

- Safety and Compliance:

- Chemical Feed Systems: pumping systems are integral for the controlled addition of chemicals in compliance with safety and regulatory standards

- Emergency Response: pumps equipped with safety features, such as the Guardian System, contribute to preventing spills and leaks, ensuring the safety of personnel and the environment

Types of Chemical Pumps & Their Applications

Chemical Pump Range:

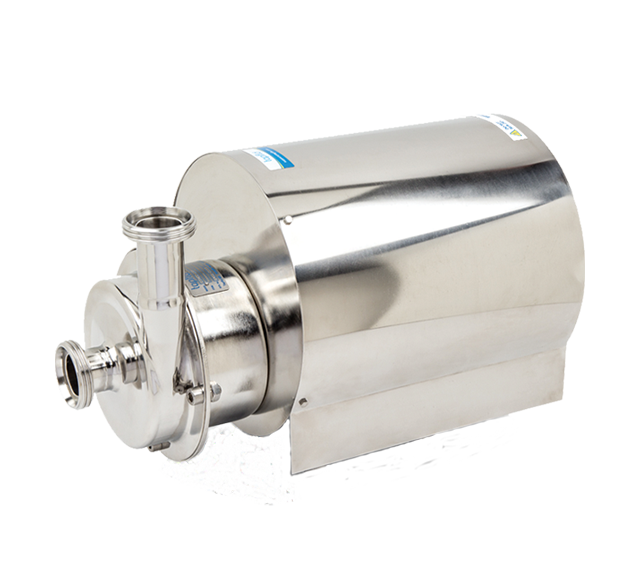

Centrifugal Pumps in Chemical Processing

Ideal for transferring chemicals from one point to another within your production facility, ensuring efficient mixing and redistribution of reactants. Tapflo UK recommends:

- CTI Industrial Centrifugal Pump: ideal for transferring chemicals, cast from Stainless Steel AISI 316L

- CTM Magnetically Driven Centrifugal Pump: features a seamless design to minimise leakage, manufactured from non-metallic injection-moulded thermoplastics

- CTS-I Industrial Self-Priming Centrifugal Pump: suitable for transferring mild chemicals and solvents, ideal for applications where suction lift is required

For those applications that require it, Tapflo UK manufactures Vertical Immersion Centrifugal Pumps that are suited for handling highly corrosive chemicals at high temperatures. These pumps are available in both Stainless Steel and PVDF.

Explore: Tapflo UK Centrifugal Pumps

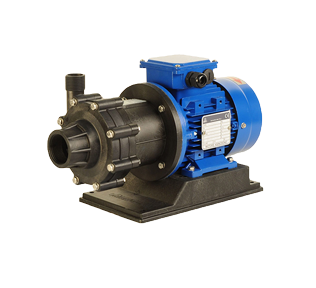

Magnetic Drive Pumps

- CTX High-Performance Centrifugal Pump: designed for chemical transfer between storage tanks and large IBC containers

Take a look at our video below explaining some of the features and benefits of the CTX range.

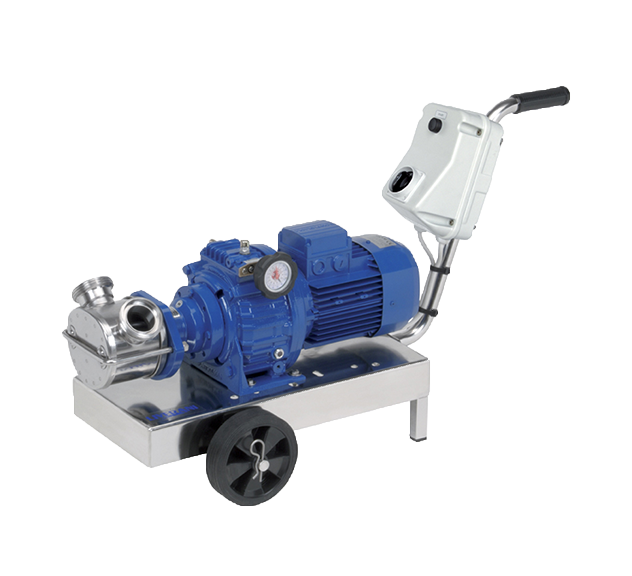

- CTM-IBC Portable Pump Unit: versatile and easily manoeuvrable, customisable for specific chemical applications

Watch: Features of our CTM-IBC decanting unit:

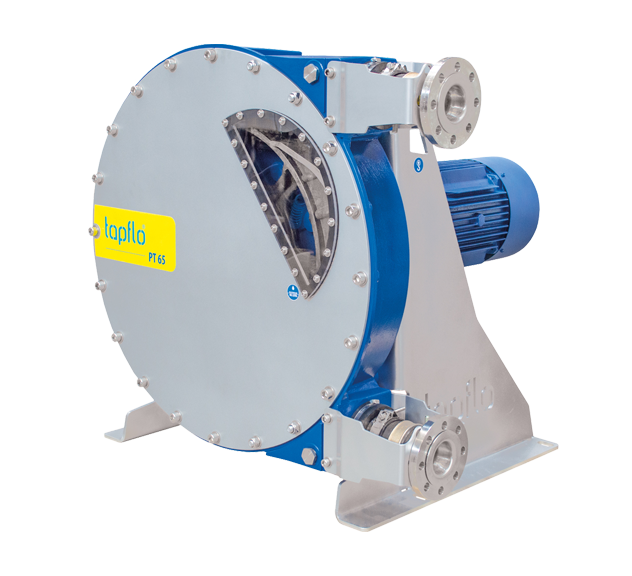

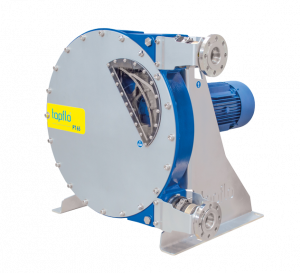

Peristaltic Pumps for Precise Chemical Handling

With only the hose in contact with the pumped product, Peristaltic Pumps are ideally suited to handling aggressive chemical, catering to diverse chemical installation needs. All hoses are manufactured from high-quality rubber that’s been compressed together to ensure long life cycle.

- PT High-Pressure Peristaltic Pump: ideal for high-pressure chemical transfer

- PTL Low-Pressure Peristaltic Pump: suitable for various chemical installations

PT High Pressure Peristaltic Pump

PTL Low Pressure Peristaltic Pump

Explore: Peristaltic Pump Hose Assemblies and Fittings

Diaphragm Pumps for Chemical Resistance

At Tapflo UK, we provide a range of Industrial and Hygienic Diaphragm Pumps in HDPE. PTFE, Aluminium, Cast Iron and Stainless Steel AISI 316L. Our Diaphragm Pumps boast no-nut, clean-face diaphragms, ensuring longevity with 70% fewer parts. Custom builds and mobile options are available.

- Plastic Diaphragm Pumps: manufactured from solid block HDPE or PTFE, providing strong chemical resistance

- Metal Diaphragm Pumps: ensures no weak spots for chemical leakages, ideal for viscous, chemically aggressive fluids containing abrasive solids

- Barrier Diaphragm Pump: protects the pump from chemical leaking into the pump housing

- Accessories – Diaphragm Pump Guardian System: this system, used as a protection device, is utilised to monitor fluid pressure, changing its output if the monitored pressure rises above or falls below the set point of the Guardian system (dependant on configuration)

For more information about our Diaphragm Pumps for chemical applications, take a look at our case study where we provided a number of ATEX PTFE and Stainless Steel AODD Pumps supplied with Active Pulsation Dampeners and Air Control Units.

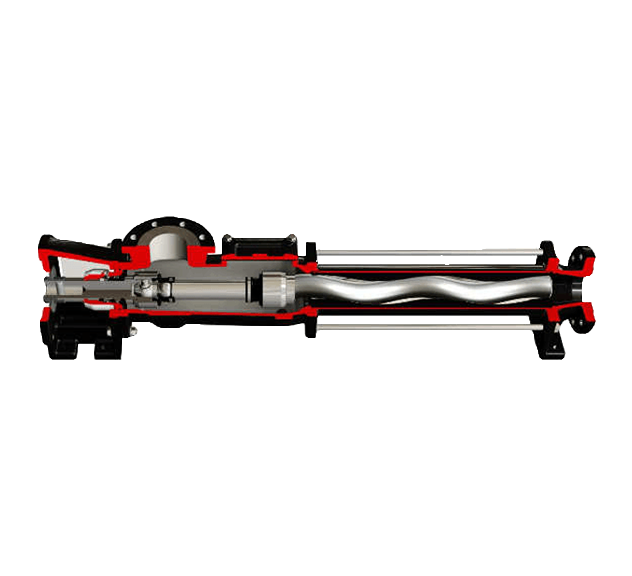

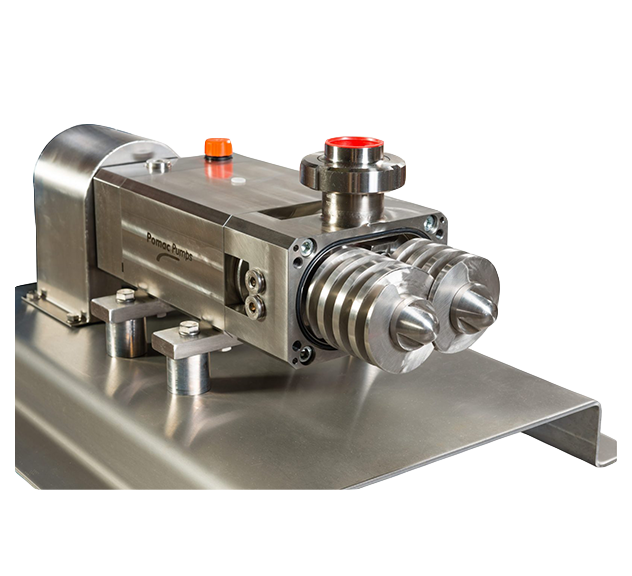

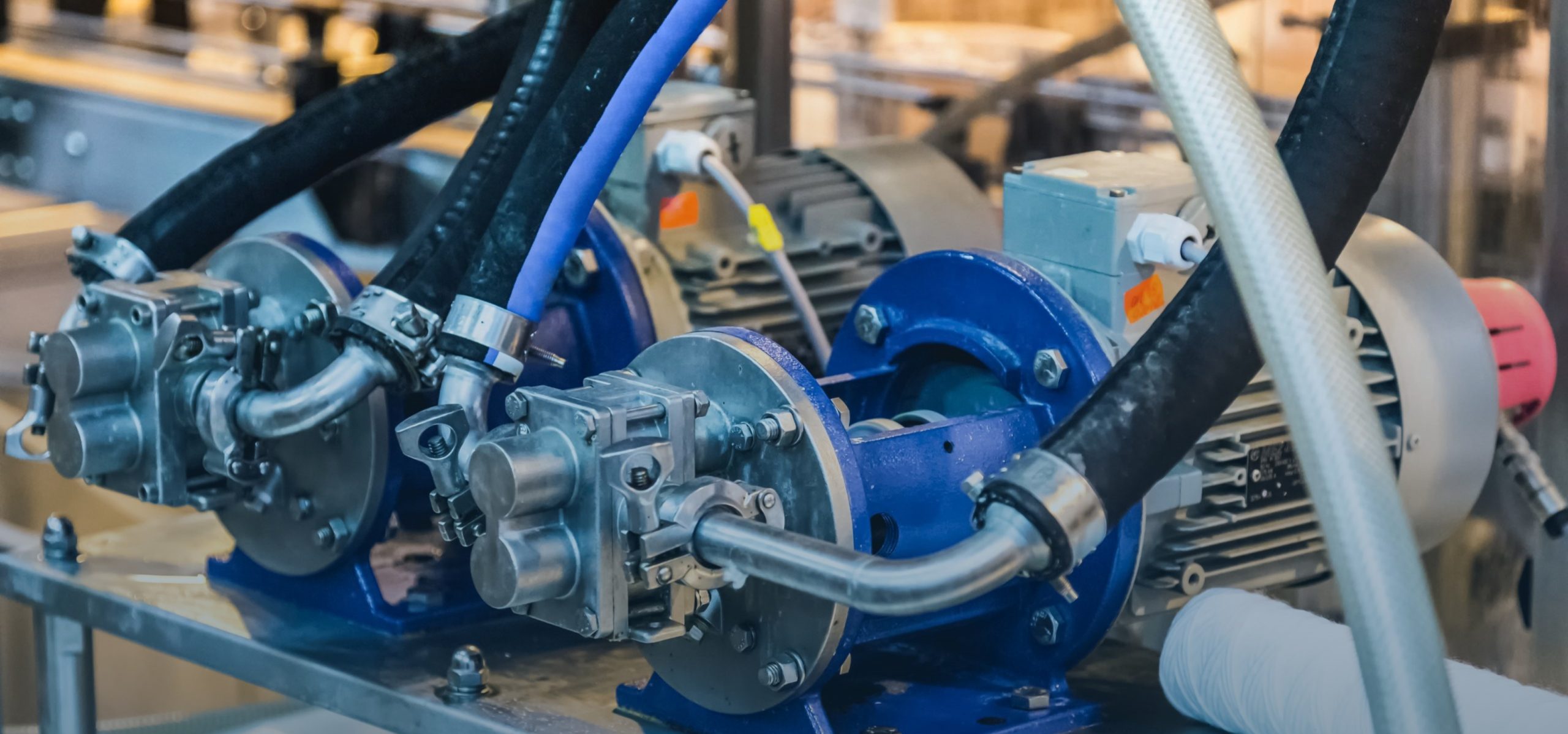

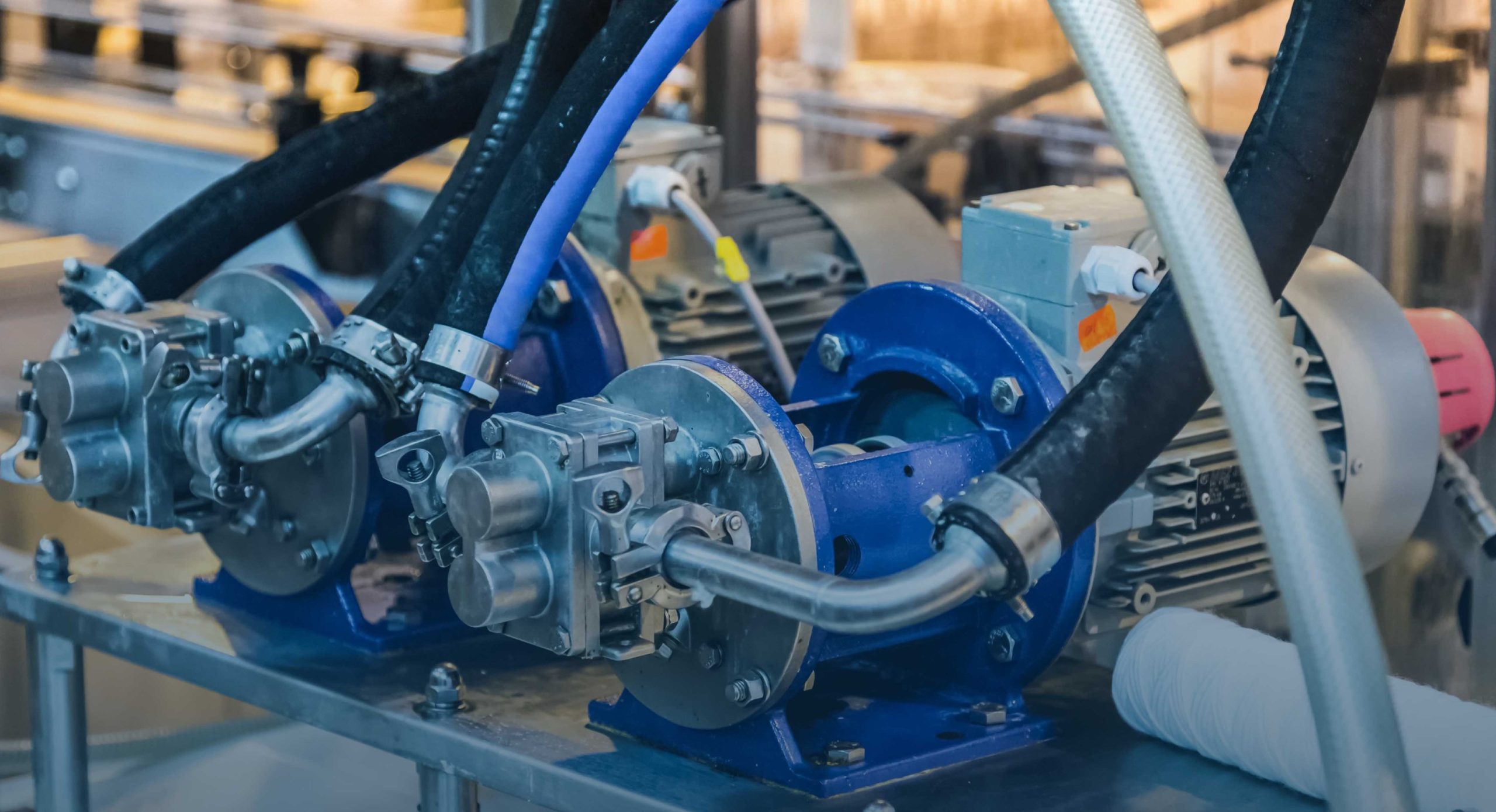

Gear Pumps for Chemical Resistance

Well-suited for various Chemical applications and ATEX-available for use in hazardous environments. The “gear within a gear working principle of these pumps means there are just two moving components during operation which is achieved by the filling of the cavities between the teeth of both the rotary and idler gears located in the pump head.

- Gear Pumps: suitable for a range of chemical applications, including fuel oils, dyes, paints and more

Chemical Pump Units

If you’re looking for more than just a pump, we have a team of Engineering Specialists available to work with you to design and manufacture a bespoke solution that meets your exact requirements. This includes solutions like our Mobile and Stationary Decanting Units to offer safety and maximum efficiency for on-site Chemical companies.

Decanting Units:

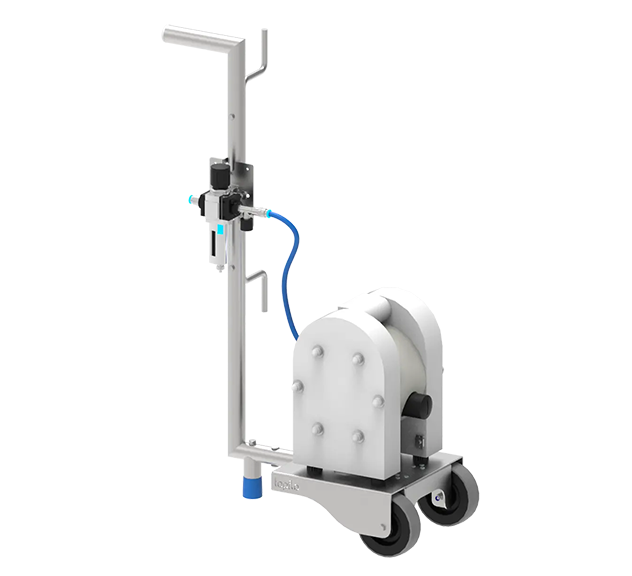

- MDU (Mobile Decanting Unit): dispenses chemicals safely, customisable with a Tapflo Diaphragm Pump, Pneumatic Batcher and more

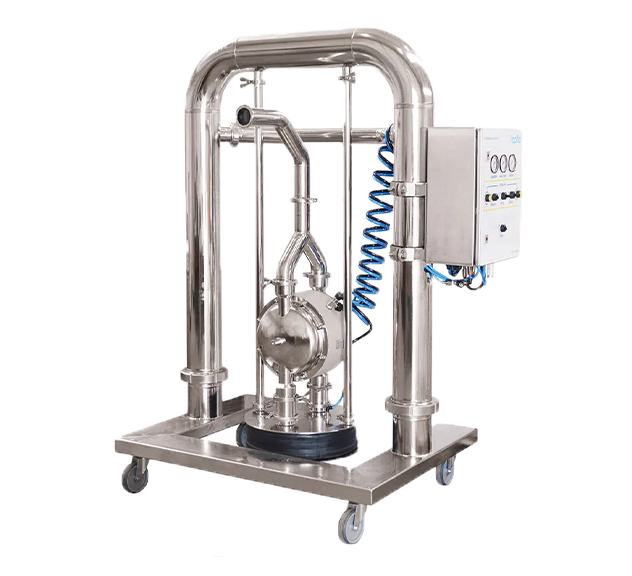

Mixing & Dilution Unit:

- Mixing and Dilution Unit: Tapflo’s SLES Mixing and Dilution Unit is a type of Chemical Pump system that allows users to dilute 70% concentration SLES to the required amount as part of their process line, enabling customers to save money in the long term on pre-diluted SLES, as well as reducing the need to store the pre-diluted fluid

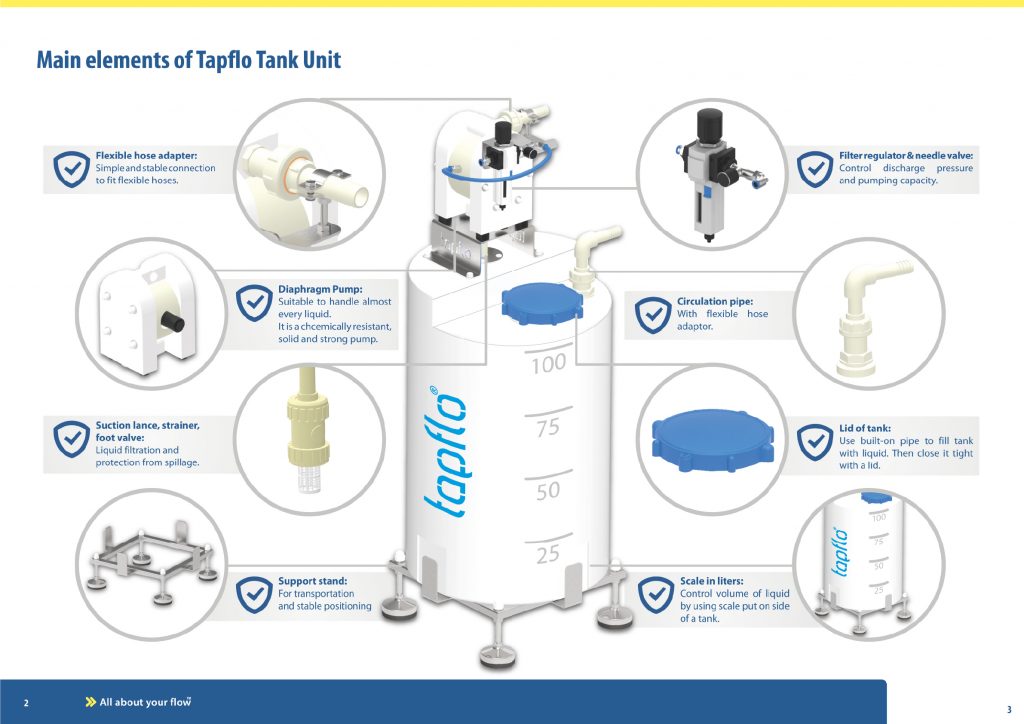

Chemical Tank Unit:

- Tapflo Tank Units: Complete solutions for storing and transferring chemicals, available in 100L, 300L, or 500L sizes. Various sizes of tanks and robust pumps in multiple executions are available together with additional equipment

Here are just some of the features our Tank Units have to offer:

What to Consider when Specifying a Chemical Pump

Safety is paramount when selecting a Chemical Pump. Tapflo UK emphasises additional safety features like the Guardian System to protect end-users from potential hazards. Custom-built solutions, such as MDUs and Tank Units, ensure maximum efficiency and safety for on-site chemical processes.

Conclusion

Tapflo UK takes pride in offering tailored solutions for various chemical applications. From Centrifugal and Diaphragm Pumps to specialised units and safety features, our comprehensive range ensures reliability and safety. Contact Tapflo UK’s pump specialists today to find a Chemical Pump solution tailored to your specific application and technical requirements.