Application Details

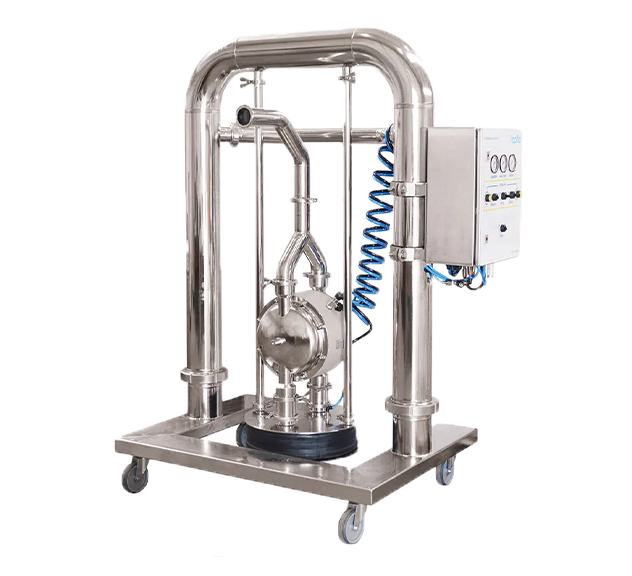

A customer approached Tapflo UK looking for a pump that could be built into a CIP Skid System. The system would be taken between sites to service machinery with a Caustic Solution for CIP. Other requirements:

- Flow rate of 15 m3 per hour

- Discharge pressure needed to be 5 Bar

- Had low NPSHr requirements

- Max temperature would be 85°C

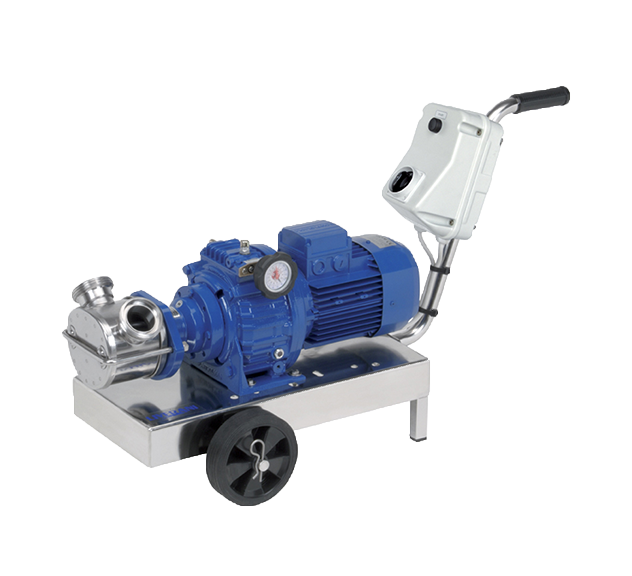

Pump Solution

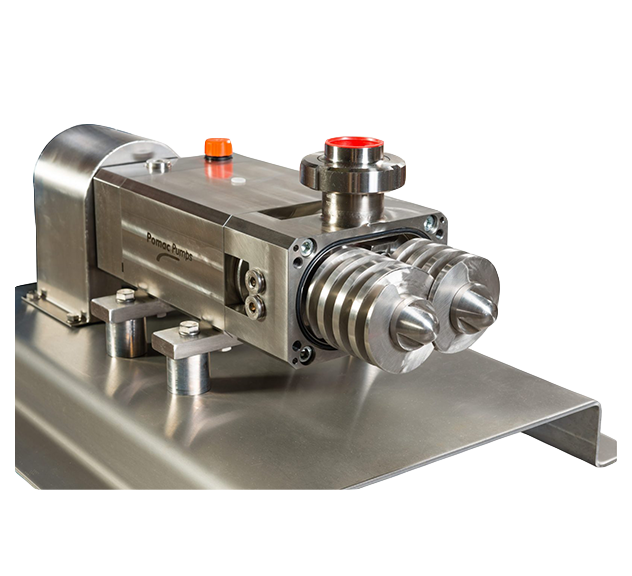

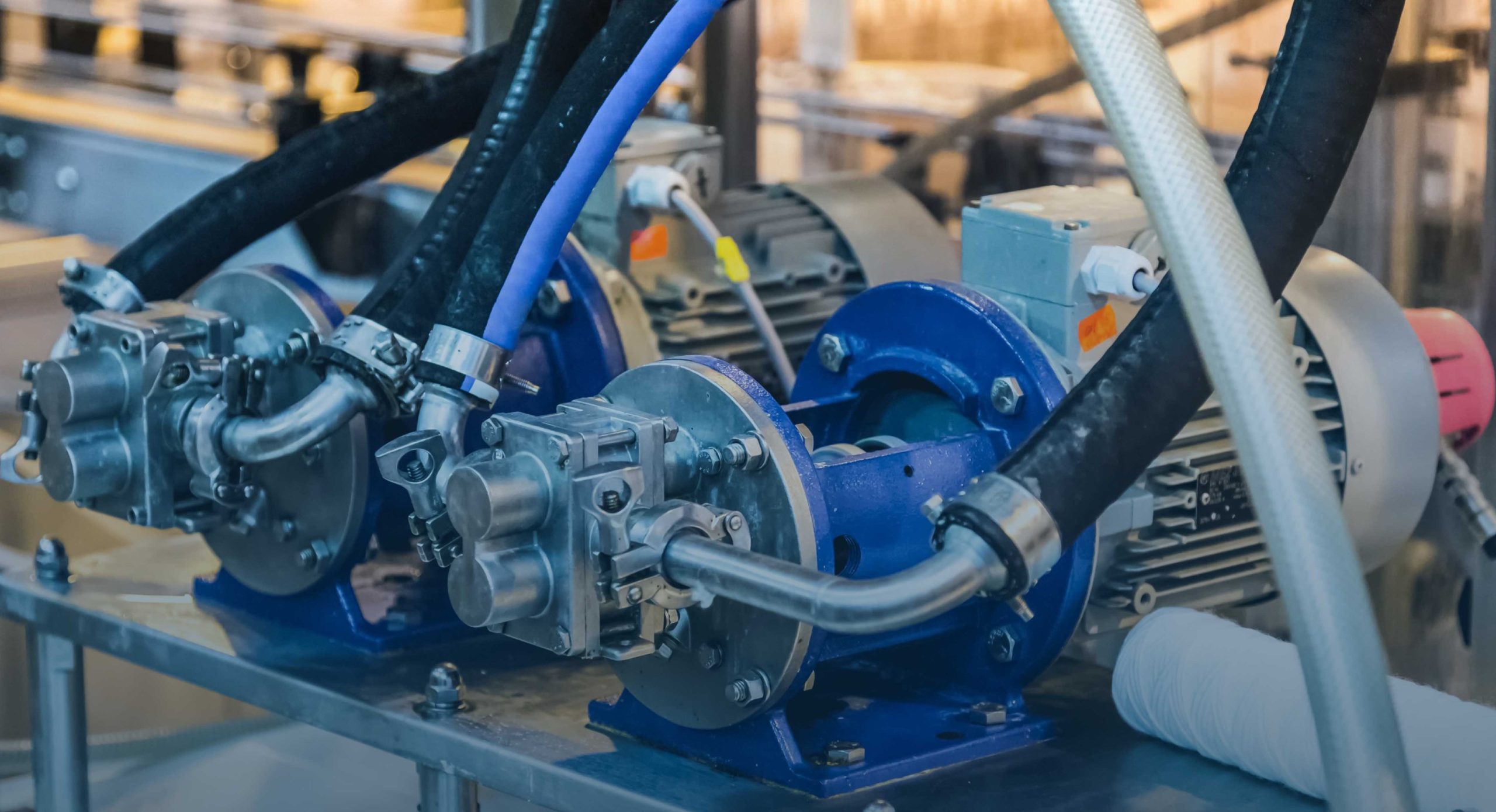

Tapflo UK is the UK exclusive partner for Pomac Pumps, their CPC Pump was a perfect fit for our customer’s application. Alongside the CPC, we also supplied ancillary equipment required for the skid:

- 1 ½” tri-clamp with counterparts

- ¾” tri-clamp for pump drainage

- 5kw motor

- Hygienic Turbine Flow Meter with LCD display for accurate readings

- Hygienic strainer which has a back pull design for easy and quick filter changes

- 1 ½” tri-clamp pressure gauge

All parts supplied by Tapflo UK were sent to the customer who built the skid

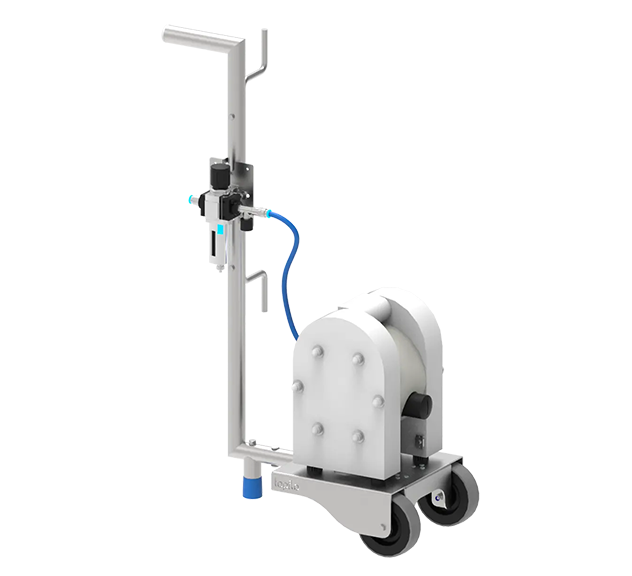

themselves to meet their design. Tapflo UK has a team of in-house engineers who are available to design and manufacture solutions such as skids and mobile decanting systems if you’d like to take advantage of this service, contact our team.

Our team also helped the customer to calculate the required size of pipework and pipework velocity to ensure that the system would work efficiently.

Features & Benefits

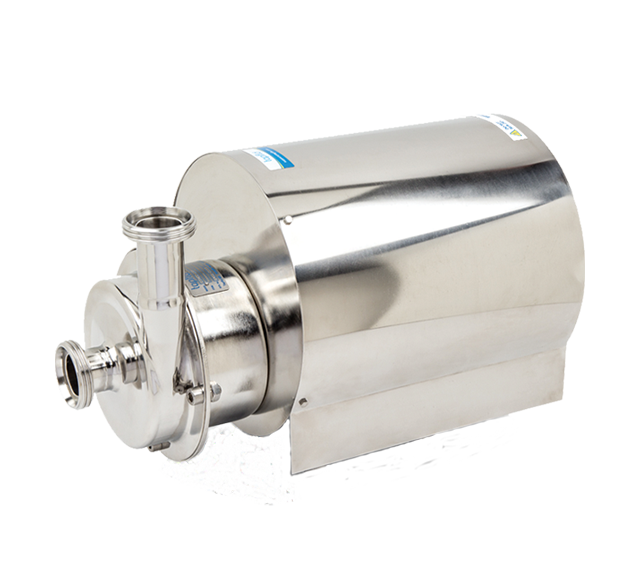

So why was the Pomac CPC Sanitary Centrifugal Pump chosen?

The pump is fully EHEDG approved, manufactured from high-quality metals with a surface finish of 0.8 as standard or 0.5 upon request. This ensures the pump is in perfect condition for sanitary applications including CIP and SIP.

The CPC Pump is a high-quality solution at a cost-effective price and has a compact design which ensured the pump would fit into the customer’s skid design.

This pump can also achieve high head to low flow discharge pressures which this system required and was delivered to a lead time that suited the customer, providing an all-around solution that met the customer’s requirements perfectly.

The CPC solution also featured a clamped drain plug port at the bottom of the pump casing, this allows the pump and system to fully drain once the customer has finished completed their on-site servicing.

You can view the full range of EHEDG rated Pomac Pumps products on our website or speak to a member of the team to find our ideal solution. We work closely with our partner, Pomac Pumps, to supply high-quality Sanitary Pump solutions to the UK on their behalf.