What is a Diaphragm Pump?

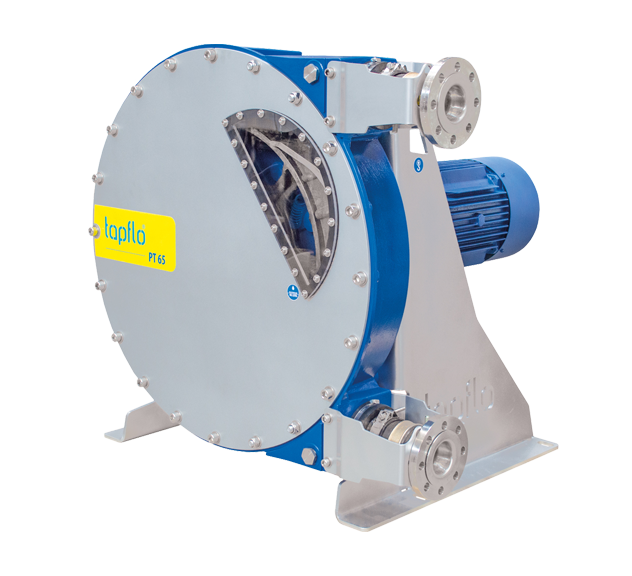

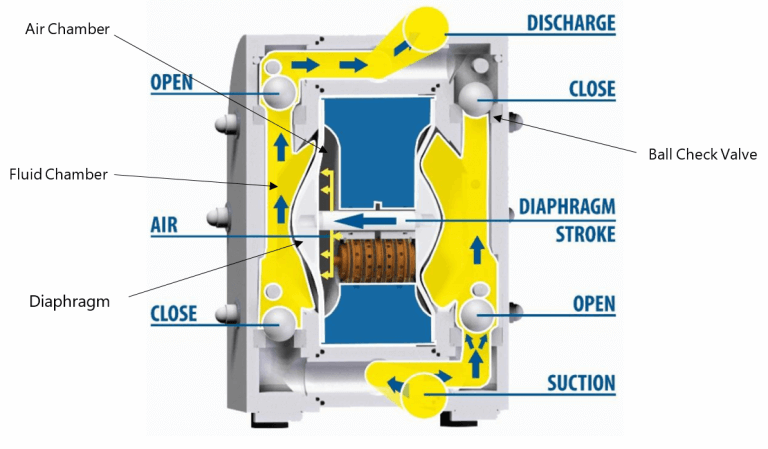

A Diaphragm Pump is a type of Positive Displacement Pump that uses a set of two internal diaphragms, either made from PTFE or rubber, that work simultaneously to create pressure to push fluid through the pump. The diaphragms operate the internal valves on the side of the pump which help to control flow direction and fluid quantity being transferred to the discharge outlet. Tapflo UK’s Diaphragm Pumps are able to self-prime up to 5m from a dry suction pipe or 8m from a wetted pipe.

Diaphragm Pumps are one of the most common and effective pumps on the market today, offering the ability to pump high volumes at low pressures, and robustness to withstand a variety of applications.

The main types of Diaphragm Pumps Tapflo UK supplies include:

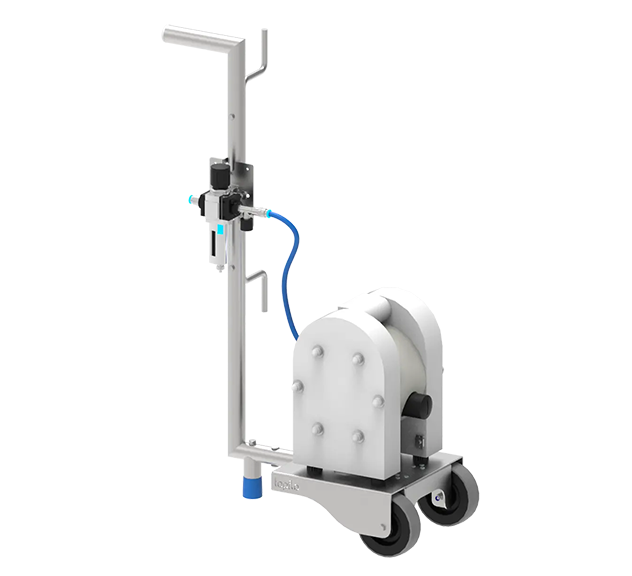

- Air-Operated Diaphragm Pumps: these pumps use compressed air to drive the diaphragms, making them suitable for applications where electricity may not be readily available (or in hazardous environments)

- Electric Diaphragm Pumps: these pumps are powered by electricity and are ideal for continuous and high-volume pumping tasks

- Hydraulic Diaphragm Pumps: these pumps are powered by hydraulic fluid, making them ideal for applications requiring high-pressure and precision pumping

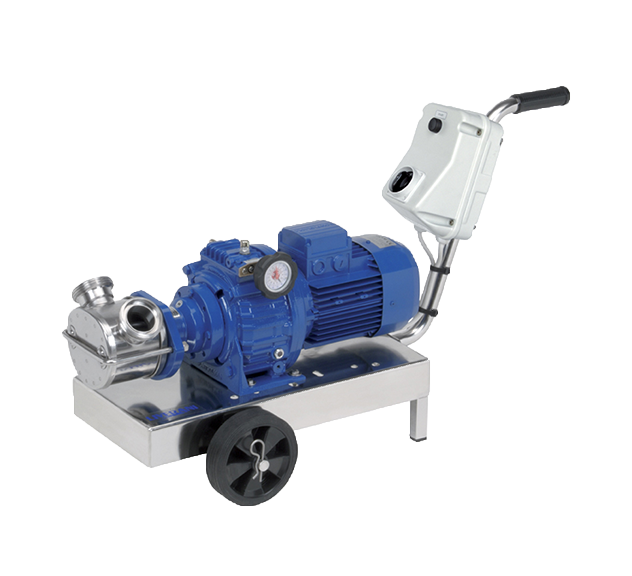

- Sanitary Diaphragm Pumps: designed with materials and features compliant with sanitary standards, these pumps are ideal for the Food and Pharmaceutical industries where maintaining hygiene and product integrity is crucial

- ATEX-Rated Diaphragm Pumps: designed to meet ATEX and other explosion-proof standards, these pumps are used in potentially hazardous environments where safety is a concern

How Does a Diaphragm Pump Work?

As there are so many variations on the market for Diaphragm Pumps, their working principles will all differ slightly. For example, there are Diaphragm Pumps that can move a small quantity of material per minute – and then there are those that can move hundreds of litres of material in a minute. It all depends on the size of the pump, operational speed and the application you will be pumping.

The standard operating principle of a Diaphragm Pump sees one of the diaphragms creating a suction to draw a set amount of fluid into one side of the pump. The other diaphragm will then drive the same volume of liquid through the outlet port from the other side of the pump. Tapflo’s core Diaphragm Pump range is air-operated, meaning it is powered by a compressed airline.

Advantages of Diaphragm Pumps

When it comes to Diaphragm Pumps, there are multiple key advantages, including:

- Self-Priming Capability: Diaphragm Pumps are self-priming, meaning they can automatically create a suction lift to draw fluid into the pump without the need for external priming. This is especially useful when dealing with challenging fluid transfer situations

- Versatile Fluid Handling: Diaphragm Pumps can handle a wide range of fluids, including corrosive, abrasive, viscous and shear-sensitive materials

- No Seals or Glands Required: Diaphragm Pumps don’t rely on seals, packing or glands, which are common wear and maintenance points in other pump types

- Dry-Running Capability: Diaphragm Pumps can operate under dry-run conditions without damage

- Ability to Handle Solids: Diaphragm Pumps can handle fluids containing small solids or particulate matter

- Bi-Directional Operation: Diaphragm Pumps can work in both directions, allowing for reversible flow, which is advantageous in applications requiring backflushing or bidirectional flow control

- Consistent Flow and Pressure: Diaphragm Pumps offer steady and pulse-free flow, making them ideal for applications requiring precise and consistent fluid transfer rates and pressures

- Reliable Performance in Variable Conditions: Diaphragm Pumps are less sensitive to changes in system pressure

- Low Maintenance Costs: Due to their simple design and fewer wear parts, Diaphragm Pumps typically have lower maintenance costs and longer service intervals compared to other pump types

- Safe for Hygienic Applications: Diaphragm Pumps can be designed with sanitary features, making them suitable for the Food & Beverage and Pharmaceutical industries where maintaining hygiene is critical

- Leak-Free Operation: The double diaphragm design ensures containment of the pumped fluid, reducing the risk of leaks and environmental contamination

- Explosion-Proof Options: Some Diaphragm Pumps are available in explosion-proof configurations, meeting safety standards for use in potentially hazardous environments

These advantages collectively make Diaphragm Pumps a preferred choice for a wide range of industries and applications where reliable and versatile fluid handling is essential.

Diaphragm Pump Industries & Applications

Tapflo UK’s Air Operated Diaphragm Pumps can be used for an array of applications and industries. Within our range, we cater to both the industrial and hygienic sectors, offering our Sanitary Diaphragm Pumps, ATEX Rated AODDs, Powder Transfer Pumps, and our very own Low Energy Air Pump, well suited to businesses looking to reduce their energy costs and reduce their carbon footprint.

- Food & Beverage

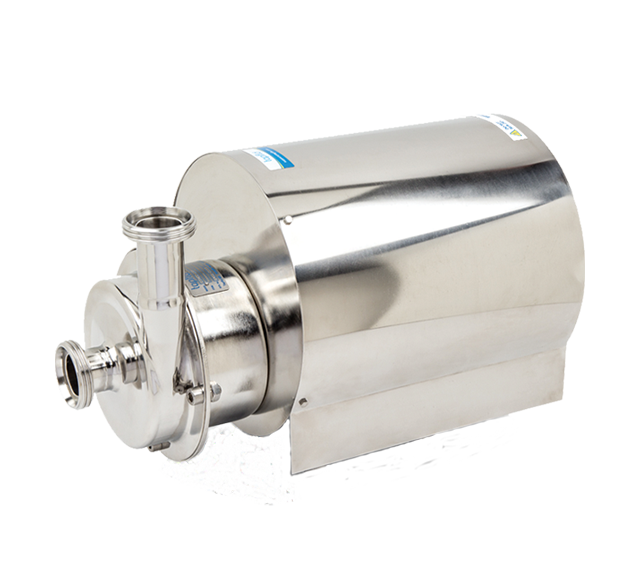

The versatility of a Diaphragm Pump means our Sanitary range is perfectly suited to the food and beverage industry. This range is specifically designed for applications intended for human consumption and can be used in the production of many applications such as dairy and beer. It is crucial for pumps being used in this industry to offer a sterile and hygienic environment for the product, which is why Tapflo’s Sanitary Diaphragm Pumps offer full FDA Approval and are manufactured to a high-quality sanitary finish of Stainless Steel AISI 316L.

For an even higher grade of hygiene, we can offer our EHEDG Aseptic Pump or our USP VI Approved Pump, more commonly used in the Pharmaceutical and Cosmetics industries to meet the most demanding cleanliness standards.

- Pulp & Paper

Believe it or not, Diaphragm Pumps can transport glue, adhesives, sodium silicate, resin solutions, and many other applications in the Pulp & Paper Industry. An example of this is in the production of cigarette paper, where a pump is used in the process of applying resin to the paper.

- Surface Coating

AOD Pumps are also excellent at transporting chemicals, including those used for Surface Coating, from storage tanks, containers, and baths. An example of our pumps being used in the Surface Coating industry can be found in our case study on providing LEAP Pumps to a company who were coating urinals. As LEAP is a Low Energy Diaphragm Pump with reduced pulsations, it was the perfect pump for this application as the coating needed to be sprayed evenly.

- Water Treatment

Diaphragm Pumps are perfect for handling a range of Waste Water Treatment applications, including the transfer of flocculent fluids, sludges, and water, as well as dosing acidic and alkali chemicals for pH control and treating water.

- Print, Paint & Varnish

Tapflo Diaphragm Pumps can also be used for the transfer, recirculation, and blending of ink, solvent-based liquids, resins, and pigments. Some advantages of using an AOD Pump within this industry include competitive pricing, the ability to handle high viscosities, and variable speeds. We have lots of options for this industry, including Mobile Decanting Trolley’s for large drums. You can check out the full range and a list of benefits in Tapflo’s Guide to Paint Pumps.

- Petrochemical

Diaphragm Pumps can be used for offshore oil drilling in order to carry oil to the surface and lubricate the drill. Diaphragm Pumps have further application uses in the petrochemical industries, such as in offshore mud drilling when rocks are brought to the surface for testing purposes.

Choosing the Right Diaphragm Pump

Selecting the right Diaphragm Pump for your operation involves the consideration of several key factors:

- Fluid Compatibility: ensure the pump materials are compatible with the fluid you intend to handle as some fluids will corrode certain pump components

- Flow Rate and Pressure: determine your required flow rate (LPM: Litres Per Minute or GPM: Gallons Per Minute) and the maximum pressure (Bar or PSI) the pump needs to deliver and match that with the pump’ specifications

- Suction and Discharge Ports: ensure the size and type of suction and discharge ports are aligned with piping and system requirements

- Viscosity: consider the viscosity of the fluid being pumped. Diaphragm Pumps can handle a wide range of viscosities

- Temperature Range: ensure the pump can handle the temperature range of the fluid being pumped

- Solids Handling: if your fluid contains solids, select a Diaphragm Pump designed for solids handling, or install appropriate filters/strainers

- Chemical Resistance: if dealing with chemicals, opt for chemically resistant diaphragm materials

- Power Source: determine the power source available (electric, pneumatic, hydraulic) and select a pump that matches it

- Noise and Vibration: assess the environment for noise and vibration restrictions as some Diaphragm Pumps are quieter than others

- Maintenance and Serviceability: consider ease of maintenance and availability of spare parts for long-term cost-effectiveness

- Safety Features: look for safety features like overload protection and leak detection, especially when handling hazardous materials

- Certifications: check to see if the pump meets industry-specific certifications or standards if required for your application

- Manufacturer Reputation: choose a reputable manufacturer with a track record of producing reliable Diaphragm Pumps, such as Tapflo UK

- Consultation: if in doubt, consult with a Tapflo UK specialist for personalised guidance based on your specific application

Consulting with manufacturers, like Tapflo UK, is essential when selecting a Diaphragm Pump. They can recommend the right pump model, size and configuration, as well as asses compatibility with fluids and environmental factors. They can also advise on safety features and compliance.

Additionally, manufacturers offer custom solutions, provide resources for installation and maintenance and expedite troubleshooting and support. They also consider the long-term cost of ownership and energy efficiency to optimise the investment decision. Overall, tapping into manufacturer expertise ensures that one chooses the most suitable and reliable Diaphragm Pump for their specific application. At Tapflo UK, our team of experts possess specialised knowledge and application expertise, ensuring the pump aligns with your operational requirements.

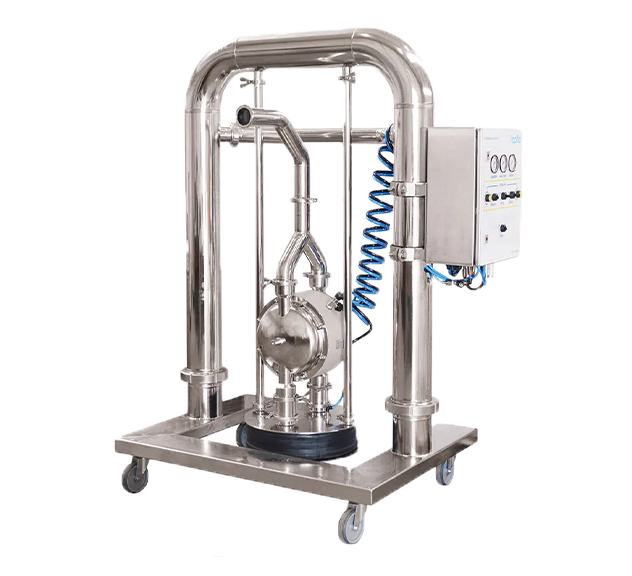

Looking to customise your Diaphragm Pump? Perhaps you’d like to integrate it into a tailored Bespoke System? Explore our Bespoke Pump Systems to discover how we can fine-tune Diaphragm Pumps, with endless customisation options available, to perfectly match your unique needs and applications.

Installation, Maintenance & Troubleshooting

Below is an installation example, showing best practice, when installing a Tapflo Air-Operated Diaphragm Pump. Please note, our air valves are constructed for oil-free air; lubricated air is not permitted and will damage the pump. However, if the air is very dry (laboratory air), the air may be lubricated with water. The maximum allowed air pressure is 8 Bar and as a preventative measure, the air must be filtered to at least 5 microns or less. The recommended air quality according to PN-ISO8573-1:2010 is particles class 6, water class 7 and oil class 4.

To facilitate the operation of the pump and cater for the above parameters, we recommend an air treatment system connected to the air supply.

These components should be included:

- Regulator to adjust the air pressure and therefore the discharge pressure generated by the pump

- Manometer to read the output pressure to the pump

- Needle valve to adjust the airflow to the pump and therefore the flow rate generated by the pump. This is especially useful when operating the pump in the lower ranges of its performance capabilities and for accurate control of flow rate

- Filter to ensure that the pumps air valve doesn’t become contaminated

The following components are included in Tapflo’s Air treatment system which can be ordered from us and installed onto the pump so that it is ready to use upon delivery.

- Gate valve for isolating compressed air supply

- Air Filter and Pressure Regulator w/ mounted Manometer

- Flexible Air Hose feeding to the pump Air Inlet

- Needle Valve for regulating the pump’s flow rate

- Flexible Suction Hose feeding to pump suction side to absorb any vibrations and water hammer effects

- Gate Valve fitted to the pump suction to enable insolation for maintenance

- Gate Valve fitted to the pump discharge to enable insolation for maintenance

- Coiled flexible piping fitted to the pump discharge to provide back pressure and also the required distance between the pump and flow gauge/meter to retain accuracy

- Flow gauge to provide an accurate readout of generated flow to ensure that the pump is working comfortably

Note: Isolation valves can be fitted to the pump ports using unions and flexible hoses are attached to fluid components by means of hose tails and hose clamps/jubilee clips.

Needing to troubleshoot your Air-Operated Diaphragm Pump? Take a look at our Troubleshooting Guide for all you need to know!

Air Operated Diaphragm Pumps

Our wide range of Diaphragm Pump systems are available for a variety of applications and executions:

- Standard Diaphragm Pumps available in Metal, HDPE, PTFE or Sanitary

- Low Energy options to reduce your business’s energy consumption and reduce costs on compressed air

- Complete Tank solutions, ideal for transferring, dosing and storing fluids

- Mobile Decanting Units including AOD and pneumatic control and monitoring system

- ATEX certified Diaphragm Pumps for potentially hazardous environments

With many Air-Operated Diaphragm pumps on the market, there is an unnecessary amount of bolts and extra parts present in the pump system which can lead to more weak points and openings for leakages to occur. Tapflo prides itself on offering a simple and easy to operate Diaphragm Pump with up to 70% less parts compared to competitors on the market.

The side housings on the Tapflo diaphragm design features side housings that can be machined from solid block HDPE, PTFE, Cast Iron, Aluminium or Stainless Steel. This design ensures that the frame is stronger to withstand aggressive fluids and increases the life of our pumps.

Air Operated Diaphragm Pump Case Study Solution:

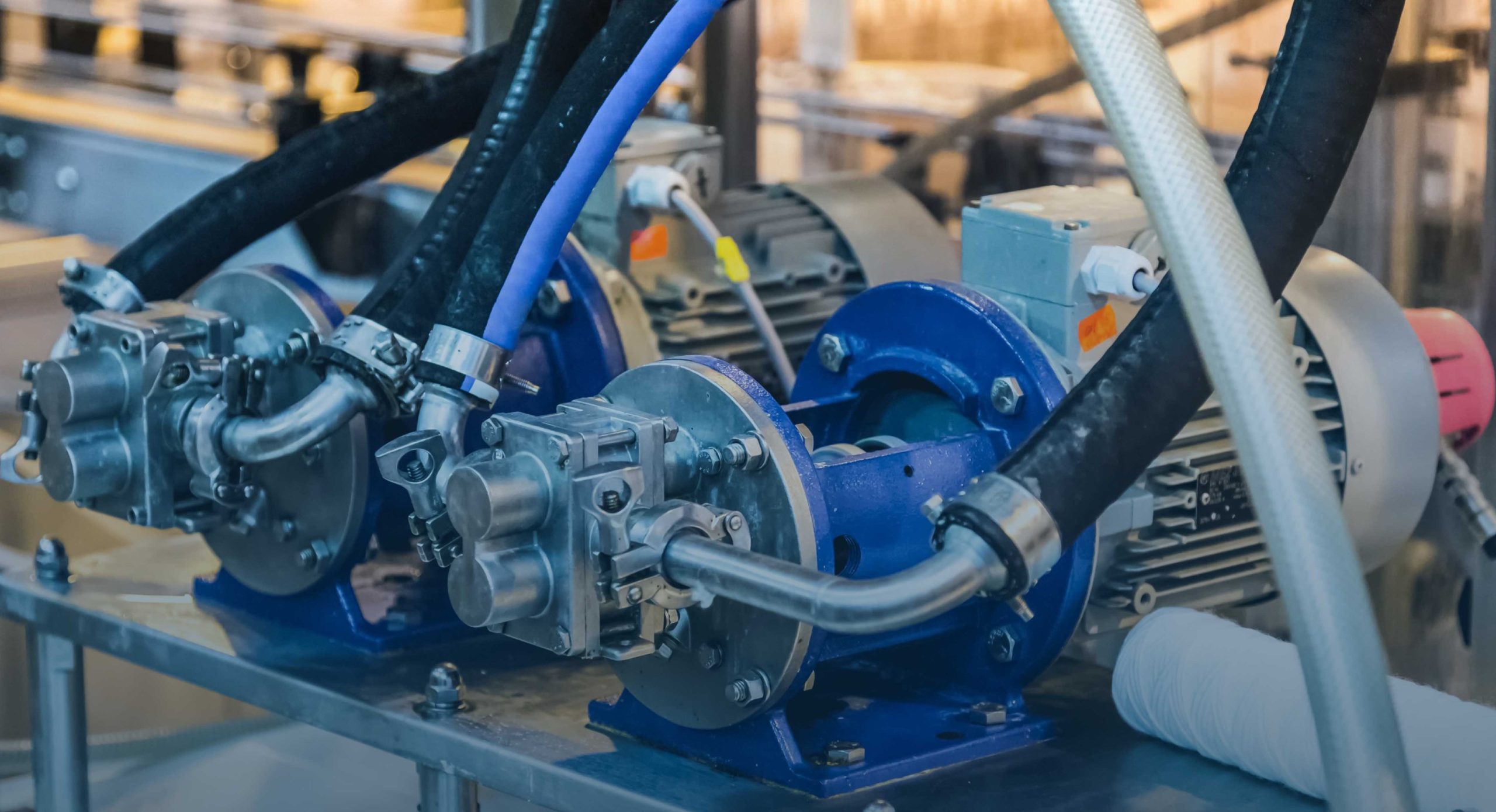

Tapflo UK provides customers with bespoke Diaphragm Pump solutions to suit their applications and industries. One, in particular, featured four Diaphragm Pumps, all T100s in HDPE, with stroke sensors. Take a look at our case study about how we provided an end-user with a suitable solution to pumping in a highly corrosive atmosphere.

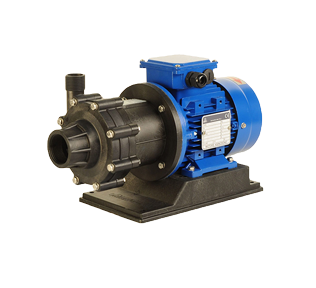

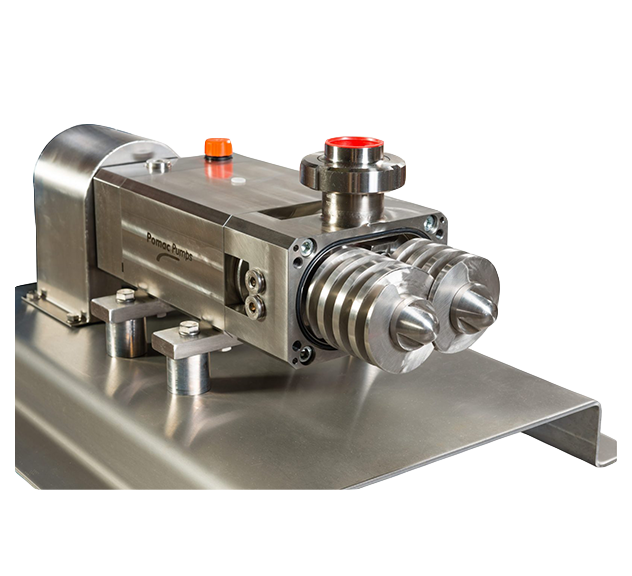

Electric Diaphragm Pumps

Tapflo also offers Electric Diaphragm Pumps, which are a great alternative if you want the benefits of a standard Diaphragm Pump but don’t have access to compressed air.

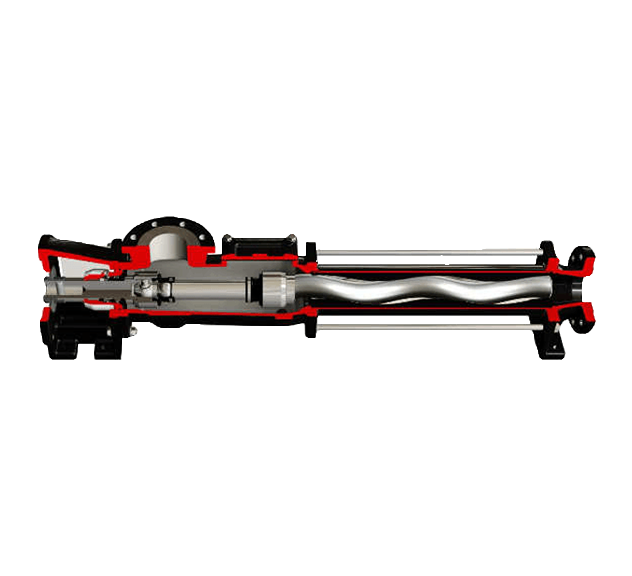

Tapflo released the Electrically Operated Diaphragm Pump back in 2019, which uses the same design effective design principle as the air operated range but is modified to create a reciprocating force (left to right) to drive the diaphragms as opposed to rotational.

This is achieved by an eccentric shaft, with a cam and piston which are used to convert the momentum from rotary to reciprocating. This force then drives the diaphragms, as usual, using one diaphragm in one of the chambers to create a suction action when being pulled back from the housing. Simultaneously, the diaphragm in the other chamber transmits the pressure to the liquid in the second chamber, pushing it towards the discharge port.

Our EODD Pumps are available in hygienic, metal, and HDPE/PTFE executions to suit a range of industries. Find out more about Tapflo EODD Pump. Why Choose Tapflo’s Air-Operated Diaphragm Pumps?

Tapflo’s Air Operated Diaphragm Pumps have a compact design and have a simple operating principle whilst still meeting the demands of our customers with both heavy industrial and high-grade sanitary applications. Below are some of the main benefits of a Tapflo Diaphragm Pump:

- Can be run dry without damage

- Machined from Solid Block HDPE & PTFE

- FDA/EHEDG Approved

- 70% fewer parts than other Diaphragm Pumps on the market

- No nut, clean face Diaphragms

- Easy to use, simple design for the operator to take apart if needed

- No need for a guarding device

- Infinitely variable flow control

- Fastest Delivery

- Flexible and easy to adjust

- Customisable with various diaphragm accessories

- Few components

- Low downtime and maintenance costs

- 5-year guarantee across the whole range of Tapflo manufactured pump products!

Considerations When Purchasing an Air Operated Pump:

- Compressed air is an expensive way to power a pump, which means that these pumps can be costly to run.

Solution: Low Energy Air Pump and compressed air

- Air Operated Pumps can be noisy when running at high pressures.

Solution: As LEAP technology can run at a lower flow, using less compressed air reduces noise pollution.

- The flow of air from air pumps can be uneven.

Solution: If your application requires a steady flow of air then ask the team about our Active Pulsation Dampener

Can a Diaphragm Pump Run Dry?

Diaphragm Pumps do have the added benefit of being able to run dry without damage to the pump! However, as a general rule, dry running is not usually recommended for long periods of time as it could cause higher wear to internal parts, due to there being no fluid within the pump to prime the internals.

To avoid dry running your pump unnecessarily, we recommend using a Guardian System. This accessory is effective at monitoring the fluid discharge pressure of the pump, which stops if the pressure falls below a set point. They are a great alternative to having an operator manually shut off the pump when it’s finished running every time and can also be used for deadhead, stop/restart, and barrier protection.

Another way to avoid dry running your pump is to use a level control, which can also be purchased from Tapflo UK and will work with any Diaphragm Pump. The level system monitors the level of media on the suction or discharge and can be set to either a high or low level, which will switch the pump off when the levels reach a set point, meaning an all-around easier solution for you!

Diaphragm Pump Material Options

Diaphragm Pumps do have the added benefit of being able to run dry without damage to the pump! However, as a general rule, dry running is not usually recommended for long periods of time as it could cause higher wear to internal parts, due to there being no fluid within the pump to prime the internals.

To avoid dry running your pump unnecessarily, we recommend using a Guardian System. This accessory is effective at monitoring the fluid discharge pressure of the pump, which stops if the pressure falls below a set point. They are a great alternative to having an operator manually shut off the pump when it’s finished running every time and can also be used for deadhead, stop/restart, and barrier protection.

Another way to avoid dry running your pump is to use a level control, which can also be purchased from Tapflo UK and will work with any Diaphragm Pump. The level system monitors the level of media on the suction or discharge and can be set to either a high or low level, which will switch the pump off when the levels reach a set point, meaning an all-around easier solution for you!

What Types of Diaphragm Pumps are available?

Want to find our more about Tapflo UK’s range of Diaphragm Pumps? In this video below, our Sales Executive, Steve, talks us through the extensive range Tapflo UK supply, as well as the benefits and uses of each!