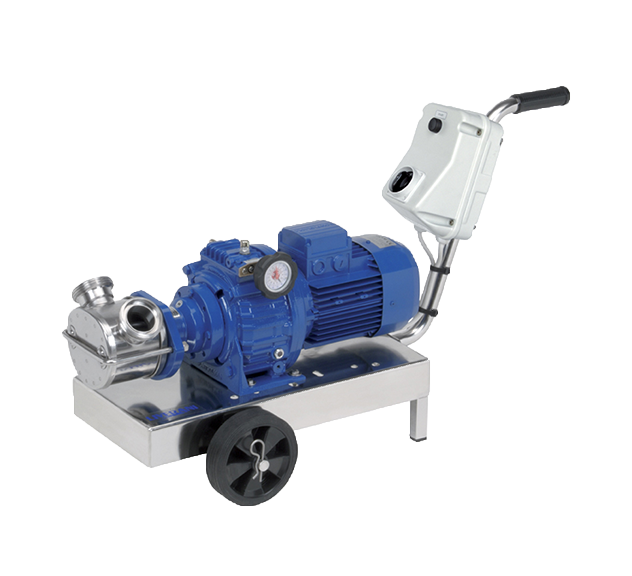

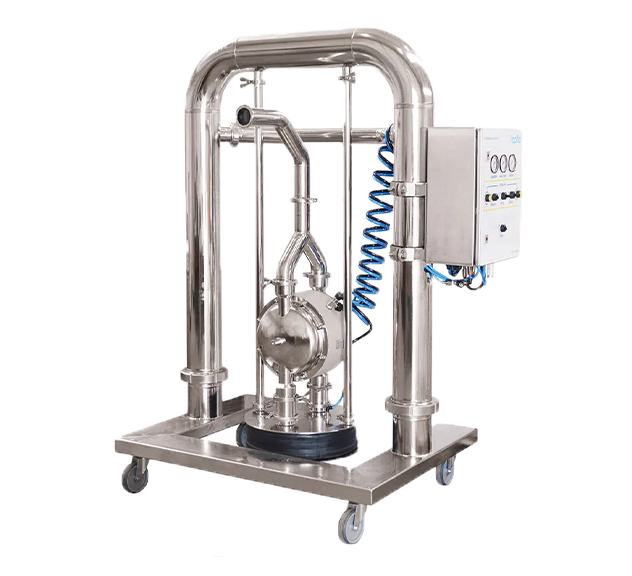

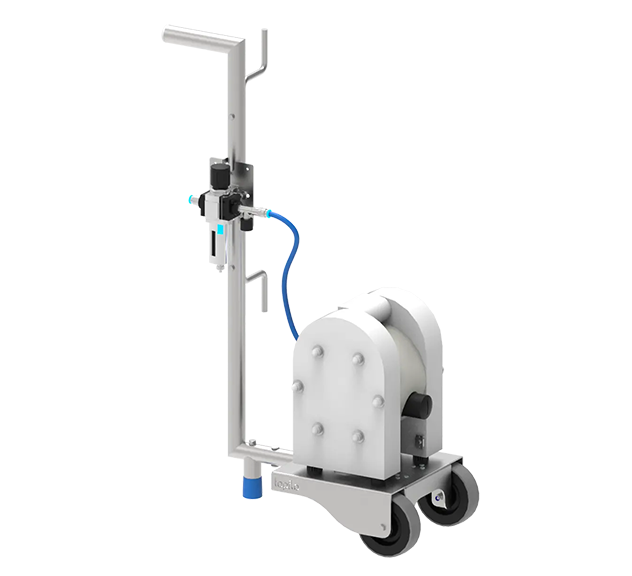

Salvatore Robuschi is an Italian Pump Manufacturer building customer-orientated Centrifugal Pump systems since 1935. They pride themselves on developing modular Centrifugal Pumps, tailored to individual customer needs in various material and hardware combinations that are ideal for handling fluids that a standard Centrifugal Pump would struggle with. Find out below the plethora of benefits the Salvatore Robuschi range has to offer!

Salvatore Robuschi Pump Benefits

Salvatore Robuschi Centrifugal Pumps absorb energy costs

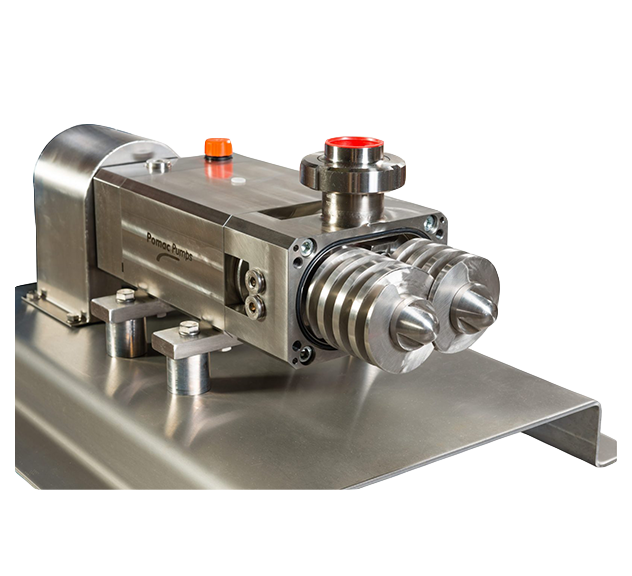

Lost Wax Micro-Cast Impellers

Lost Wax Micro-Cast Impellers

During the lifespan of a Centrifugal Pump, typically 5% represents the cost of purchase, 65% represents the cost of Electrical Energy (Absorbed Power Consumption) & 30% represents the cost of Installation & Maintenance. Pumps in Alloy Steels have an approximate 10% loss in performance when compared to their Cast Iron counterparts. Through the use of micro-cast (Lost Wax) impellers, this imbalance can be corrected to provide near identical performances.

This means that pumps produced in this method can represent considerable energy savings as well as reduce NPSHr values (Nett Positive Suction Head required). The graph to the right represents the energy saved on 5000 Hrs of operation of a pump with a traditionally cast impeller (top line) vs a Micro-Cast Impeller (bottom line). 10 kW more power is absorbed by traditionally cast vs micro-cast.

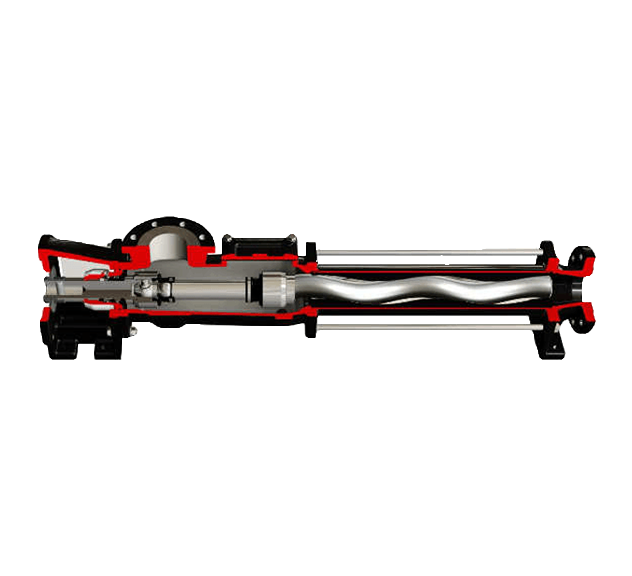

Pumping solids in suspension and dissolved gases without compromising on the Centrifugal Pumps’ performance:

Lost Wax Micro-Cast Impellers Open Impeller

Vortex type impellers are commonly used in pumps to convey fluids with solids in suspension. These typically are relatively inefficient when compared to Open impellers with wear plates and generally result in high operating costs that are not always justifiable. By using open impellers with wear plates an approximate 30% reduction in absorbed energy costs can be expected, which means the up-front capital investment can be recouped in a matter of months.

Vortex Type Impellers:

- “Soft” Pumping

- Reduced risk of clogging

The large free passage between the casing and the recessed impeller allows the Centrifugal Pump to pass solids up to 90% of the diameter of the discharge port. This configuration also facilitates the protection of the casing and gasket housing from abrasion and the passage of long filamentous or delicate solids without damage.

The most economical range of Centrifugal Pumps for arduous applications:

The HD, HG & RS Close Coupled Centrifugal Pump ranges were developed to face the need for pumps for arduous and difficult applications whilst ensuring a reduced cost of purchase. The use of Micro-Cast components, simplicity of manufacture & the modularity of its components (Open/Closed/Vortex Impellers with various sealing options) enables them to be used in heavy-duty conditions but with lower purchase and maintenance costs.

Interchangeability:

The Process & Close Coupled Centrifugal Pump ranges (HD, HG & RS) are produced according to ISO 2858/5199 dimensions norms and are therefore interchangeable with themselves and other pumps produced to this standard.

Modularity:

All Salvatore Robuschi Centrifugal Pumps are built with modularity in mind in order to reduce the cost of spare parts and warehousing. Many pumps will feature common & interchangeable spare parts.

Quick delivery times:

Average delivery times of 15-30 working days, including the ISO 2858/5199 Process Centrifugal Pump range.

Quick & ready spares availability:

Shipment of spare parts (including seals) can be made within 24/72 hrs.

To view the full Robuschi Industrial Centrifugal Pump range, visit the product page. We’ve also included videos from Salvatore Robuschi about their products so whether you’re looking for something specific or you just want some visual information, fast, we’ve got it covered on the product pages. All Robuschi Centrifugal Pumps are made to order so whatever your requirements are, we’ve got it handled! To get the ball rolling on owning a Robuschi Centrifugal Pump, contact our team today.

Ability to Pump a Variety of Applications

Salvatore Robuschi Pumps are ideal for large industrial applications, such as:

- Distillation

- Purification

- Cooling

- Chemical Transfer

- Tanning & Textiles

- Waste Water Treatment: Preliminary Screening, Primary Treatment, Clarification, Dissolved Air Flotation (DAF), Ultra-Filtration, Demineralisation (UF & RO), Back Washing

- Anaerobic Digestion: Digester Recirculation, Anaerobic Digestate Concentration, Forced Circulation Vacuum Evaporation, Multiple Effect Evaporation

- Wet Scrubbers: Blast Furnace Scrubbers & Wet Scrubbers

- Open Pit & Sump Unloading

- Pumping process fluids & slurries with suspended solids

- High-Temperature Transfer up to 500ºC

- Solvent & Fuel Transfers

Material Options

Robuschi stock components enable them to produce almost any size of the pump in either Stainless Steel AISI 316 or Cast Iron within a few weeks, enabling them to respond quickly and effectively to a wide variety of customer demands and applications, which other manufacturers would struggle to achieve.

More exotic materials of construction are also available on request to cater for more arduous applications. Some of these include:

- Duplex Stainless Steel with wetted parts in SAF 2205

- Super Duplex with wetted parts in SAF 2507

- AISI 304L & 904L

- Sanicro 28

- Hastelloy C & B

- CA6NM (Wear Resistant Material) with a 400 Brinnel Hardnes

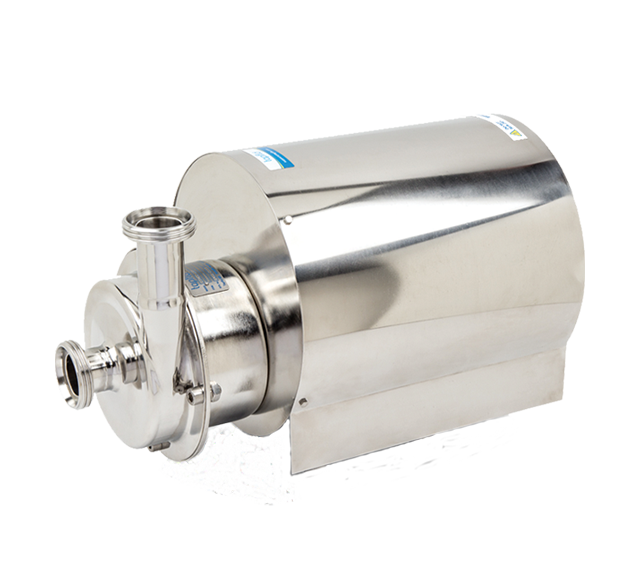

Highly Versatile for Sanitary and Industrial Applications

Salvatore Robuschi Pumps are not supplied according to sanitary certification levels. However, FDA approved seals and elastomers can be fitted as well as DIN 11851 hygienic connections and motor shrouds to enable them to be used in many food applications such as:

- Fruit & Tomato Processing Lines: Receiving, Washing & Sorting, Rotary Drum Filtration, Hot Break, Forced Circulation & Evaporation, Tube In Tube Pasteurisation, Cooling Towers

- Meat / Fish & Poultry: Fishmeal Stick Water, Meat & Offal Processing, Slaughterhouses

- Distillation & Wine Production: Distillation, Stillage & Cross Flow Filtration

- Vacuum Fillers

- Spiral Pasteurisers

- Dirty Hot Oil Transfers

- CIP

- Dissolved Air Flotation

- Effluent Treatment

Salvatore Robuschi Pumps are some of the most versatile and robust systems which we are proud to supply as part of our process pump range here at Tapflo. Take a look at the salvatore robuschi pump portfolio brochure for more information including technical specifications.