When looking for a pump that can work for almost any of your requirements, the popular diaphragm pump is a great option to consider for your application. Here at Tapflo UK, our range of Air Operated Diaphragm Pumps are renowned for being an extremely versatile option for many different fluid viscosities, flow rates, air pressures and temperatures. By understanding the correct way to install a pump for your requirements will help to greatly improve the long life of the pump and minimise downtime. So what are the different type of installations available and how do you install a diaphragm pump?

Types of Installations

The type of installation you require will be dependable on the application being pumped. The Tapflo Air Operated Diaphragm Pump is flexible to many types of installations. Furthermore, as the inlet and outlet ports can be rotated through 180º piping systems, this reduces the work of the pump and the installer! Below are 3 types of installations in which Tapflo Diaphragm Pumps can be operated in:

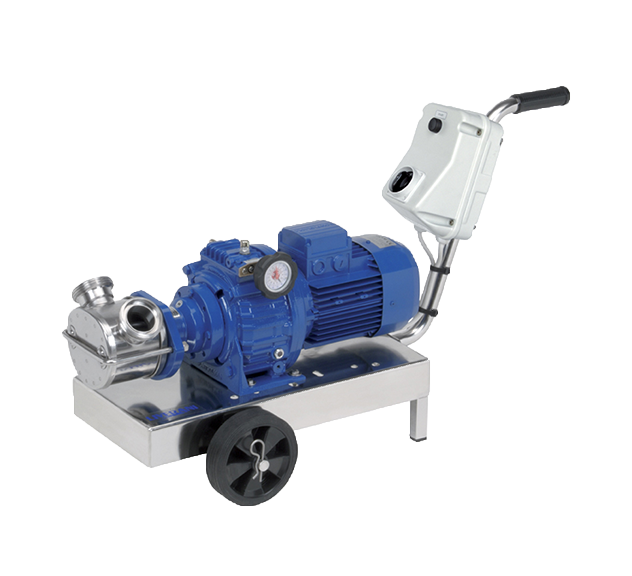

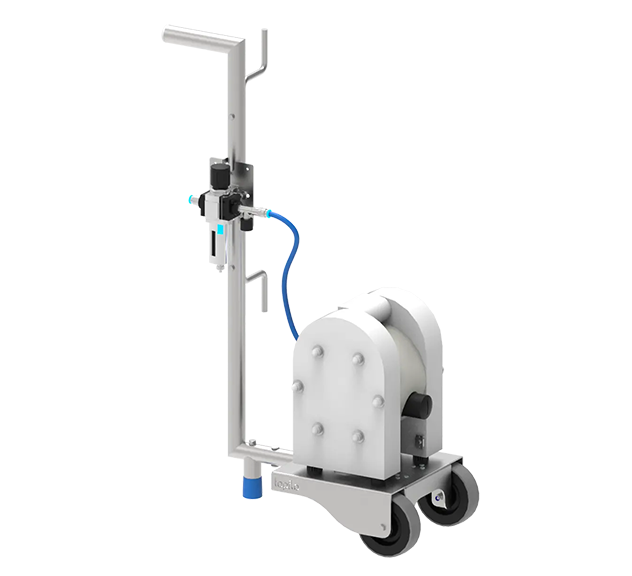

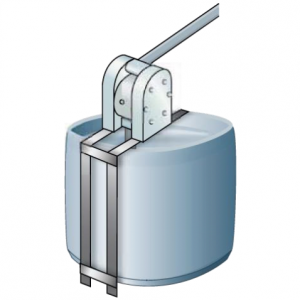

Trolley Mounted

Another great install option, especially for the chemical industry, is for your Air Operated Diaphragm Pump to be on a mobile decanting unit. This includes a Pneumatic Batcher, PoD Valve (Point of Dispense) and the diaphragm pump all mounted onto one of Tapflo’s bespoke trolley unit’s. These are designed and manufactured in house to suit each clients requirements and can accommodate 20L, 25L or 205L chemical containers. This option is ideal for chemical transfer applications to reduce the risk of carrying containers to different areas of your factory operations. If you would like to find out more about our trolley mounting options, take a look at our mobile decanting unit page.

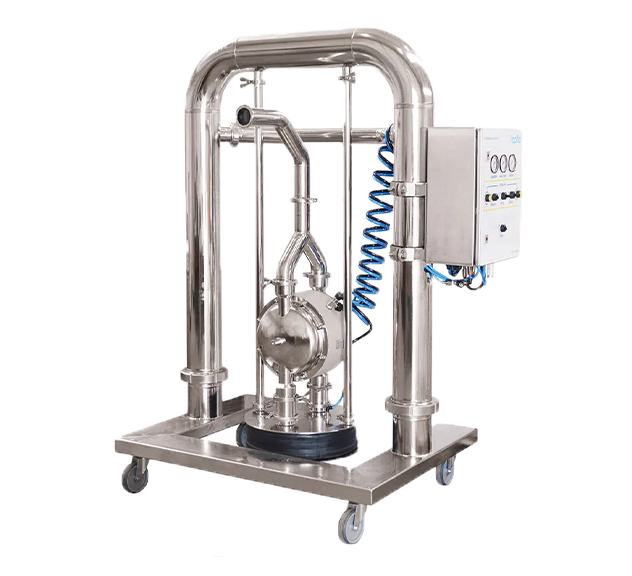

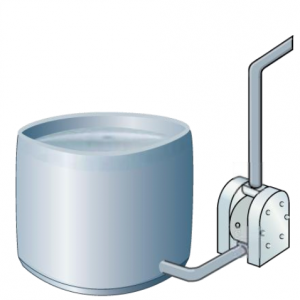

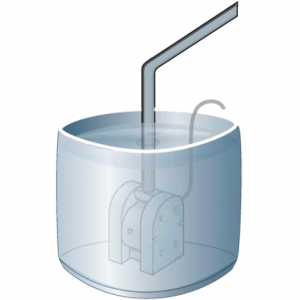

Floor or Wall-Mounted

Tapflo’s stationary decanting system allows for a diaphragm pump to be installed either floor-mounted, where the upstand with the pump and batcher are all mounted within, or wall-mounted, with the pump and air preparation mounted on a wall bracket. The wall-mounted option is can be an advantage especially when there is limited space available on the factory floor. Take a look at our stationary pump systems here.