EUROPE

ASIA & PACIFIC

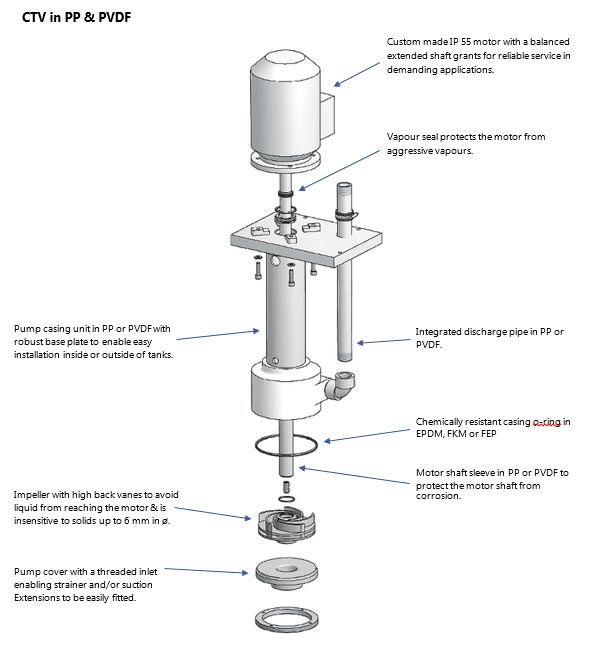

The PP & PVDF Immersion Centrifugal Pumps form part of the CTV range and are highly reliable pumps designed for fluid transfer and circulation in corrosive Chemical applications. These pumps are commonly used for surface treatment baths, circulating through filters and nozzle ramps. The PP version is suited to handling chemicals at temperatures up to 70°C and the PVDF version is suited to handling hot acids at temperatures up to 100°C.

Max. Flow:

Max. Head:

Max. Temp:

Material:

28m³/hr

20m

100°C

Plastic

The PP and PVDF Immersion Centrifugal Pumps are specifically designed to handle highly corrosive chemicals at higher temperatures.

What makes the PP and PVDF Immersion Centrifugal Pumps great?

Options and special executions available:

Largest UK Stock

Same Day Quote

Fastest Delivery

Largest UK Stock

Same Day Quote

Fastest Delivery

Our friendly team at Tapflo UK would be more than happy to assist you further with any pump solutions, delivery information or questions you have. If you need additional support on-site, you can speak to a member of the team today to organise a site visit.

Give us a call now:

Search our pump support articles: